Anlayış Güvenlik Kenar Anahtarı İşlevsellik

Güvenlik Kenar Sistemlerinin Temel Bileşenleri

Güvenlik kenarı sistemlerinin çoğu üç ana parçadan oluşur: kendisi algılayıcı kenar, bir kontrol ünitesi ve tüm sistemi çalıştıran güç kaynağı. Algılayıcı kenar, üzerinde bir şeyin teması ile basınç değişimlerini tespit ederek adından da anlaşılacağı gibi görevini yerine getirir. Bu tespit, kontrol ünitesine uyarı sinyalleri gönderir ve kontrol ünitesi de kazaların oluşmasını önlemek için bir sonraki adımların ne olması gerektiğini belirler. Enerji bileşenlerinden gelen uygun güç kaynağı olmazsa, bu sistem uzun süreli olarak güvenilir şekilde çalışmaz. Bu yüzden makinelerin sorunsuz çalışması için elektrik konusunun doğru yapılması çok önemlidir. Teknisyenler bu tüm bileşenleri ve gün boyu nasıl etkileştiklerini anladıklarında, farklı endüstriyel ortamlarda hem işçinin güvenliğini hem de makine verimliliğini artırabilirler.

Güvenlik Kenarları Otomasyondaki Kazaları Nasıl Önler

Güvenlik kenarları, bir şey onlara dokunursa makineleri neredeyse anında durduran basınç duyarlı teknolojiyle çalışır ve bu da onları fabrikalar ile diğer otomatikleştirilmiş alanlarda oldukça önemli kılar. Bu cihazlar, ağır ekipmanlarla çalışan insanların yapabileceği hatalara karşı ilk savunma hattı olarak hareket ederek kazaları önemli ölçüde azaltır. Güvenlik kenarı sistemleri kuran fabrikalarda sektörel raporlara göre kaza oranlarında yaklaşık %30'luk bir düşüş gözlemlenmiştir. Üretim tesislerinde bu sistemlerin kurulması, işçilerin zarar görmesini engellerken aynı zamanda pahalı makineleri de koruyarak genel güvenlik standartlarını artırır.

Cevap Zamanının Acil Durumlardaki Rolü

Acil durumlarda güvenlik kenarlarının ne kadar hızlı tepki verdiği çok önemlidir çünkü daha hızlı reaksiyonlar kazaların yol açtığı zararı ciddi şekilde azaltır. Tipik tepki süresi rakamları incelendiğinde mühendisler sistemleri saniyenin kesirleri içinde harekete geçecek şekilde tasarlamaktadırlar; bu özellikle yüksek hızda çalışan ekipmanlarla çalışırken hayati derecede önemlidir. Sektörün tepki süresi konusunda standart olarak kabul ettiği değerleri bilmek, şirketlerin fabrika ortamında güvenlik gereksinimlerini karşılayan sistemleri seçmesini kolaylaştırır. Teknoloji hızla gelişmeye devam ettikçe, kısa tepki süresine sahip bir sistem seçmek otomatikleştirilmiş üretim ortamlarında işyeri güvenliği ve riskleri azaltma açısından neredeyse kritik bir hale gelmiştir. Üreticilerin çoğu, bu alandaki küçük iyileşmelerin bile yaralanmaların ve ekipman arızalarının önlenmesinde büyük faydalar sağladığını görmektedir.

Mükemmel Performans için Kritik Seçim Faktörleri

Çevresel Koşulları Değerlendirme (Sıcaklık\/Toz\/Nem)

Sıcaklık değişimleri, toz birikimi ve nem gibi faktörler, güvenlik kenarı anahtarlarının pratikte ne kadar iyi çalıştığını gerçekten etkiler. Bir anahtar seçerken, kullanılacağı ortamın türüne dikkatlice bakmak önemlidir çünkü tüm güvenlik kenarları aynı koşulları eşit şekilde tolere etmez. Bazı modeller aşırı sıcaklıklara dayanacak şekilde üretilirken, diğerleri suya veya toza maruz kaldığında hızlıca arızalanabilir. Yağmur, kar veya güneşe maruz kalmanın yaygın olduğu dış mekan kurulumları için bu tür koşullara uygun anahtarlar seçmek büyük fark yaratır. Bu tür dayanıklı modeller genellikle doğanın tüm zorluklarına rağmen çok daha uzun ömürlüdür ve zamanla daha iyi performans gösterir.

Farklı Uygulamalar İçin Gerekli Kuvvet Duyarlılığı Uygulamalar

Seçerken safety edge switches çeşitli uygulamalar için kuvvet hassasiyeti gerçekten önemlidir. Kenar, farklı basınç seviyelerine uygun şekilde tepki vermelidir ki tüm ortamlarda iyi çalışabilsin. Büyük makineler ile daha hafif endüstriyel ekipmanları karşılaştırın - bunların tamamen farklı hassasiyet ayarlarına ihtiyacı vardır. Küçük bir konveyör bandında mükemmel çalışan bir anahtar, büyük üretim ekipmanındaki kuvvetler karşısında yetersiz kalabilir. Bunun doğru yapılması, üretimin çok fazla yavaşlamadan çalışanların güvenliğinin sağlanmasını sağlar. Çoğu üretici, güvenlik standartlarının pratik işletme gereksinimleriyle ödün verilmeden buluştuğu bir 'tatlı nokta' bulduğunu ifade eder.

Malzeme Dayanımı: Gumus vs. Poliüretan Profiller

Güvenlik kenar bantları için kauçuk ve poliüretan malzemeler arasında karar verirken şirketlerin bu seçimin dayanıklılık ve gerçek dünya koşullarında genel performans üzerindeki etkisini göz önünde bulundurmaları gerekir. Kauçuk temel düzeyde yeterli koruma sunarken, poliüretan zaman içinde daha dayanıklı olmasıyla öne çıkar. Fabrika zeminlerinde ve inşaat sahalarında gördüğümüz kadarıyla, poliüretan bantlar, kauçuk olanlara kıyasla sert muameleye ve aşırı sıcaklıklara maruz kaldıklarında çok daha uzun ömürlü olma eğilimindedir. Düşük çevrim süreleri gelir kaybı anlamına gelen zorlu ortamlarda faaliyet gösteren üreticiler için doğru malzeme yatırım yapmak her şeyi değiştirir. Ek maliyet, daha seyrek bakım ve daha az sık değiştirme ihtiyacından dolayı ilerleyen süreçte karşılanır.

Güvenlik Kenar Anahtarlarının Türleri ve Kullanım Durumları

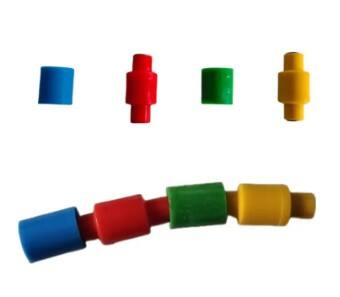

Özel Kurulumlar İçin Modüler DIY Güvenlik Kenarları

Modüler DIY güvenlik kenarları, inanılmaz esneklik ve kişiselleştirme seçenekleri sunar; bu da onları her türlü farklı kurulum için harika hale getirir. Kullanıcılar, bu sistemleri ihtiyaçlarına tam olarak göre inşa edebilir ve bu, özel kapı sistemleri veya standart ürünlerin doğru çalışmadığı otomasyon düzenekleri gibi durumlarda özellikle önemlidir. Bu özelleştirilmiş kenarların mevcut tasarımlara entegrasyon şekli, gereksiz kesintiler olmadan makinelerin sorunsuz bir şekilde çalışmasına olanak tanırken her şeyin güvenli kalmasını sağlar. Birçok kurulumcu, bu yaklaşımın uzun vadede zaman ve para tasarrufu sağladığını düşünür çünkü ileride pahalı modifikasyonlara gerek kalmaz.

Dar Uzaylar İçin Minyatür Güvenlik Kenarları

Daha büyük alternatiflerin hiç olmadığı durumlar için geliştirilen mini tip emniyet kenarları, sıkışık alanlara sığdırıldıklarında bile güvenilir bir şekilde çalışmaya devam eder. Robot üreticileri ve otomobil şirketleri, küçük bileşenlerin içine kolayca yerleşebildiği için ve güvenlik özelliklerinin düşünülmemesine fırsat vermediği için bu ürünleri severler. Montaj hatları robotlarını ya da araç sensörlerini düşünün; bu minik kenarlar, fabrika zeminlerinde ya da araç içlerinde değerli alanlardan çalmadan çalışanları ve ekipmanları korur. Üretim ortamlarında alan para demektir; bu yüzden ekstra alan gerektirmeyen güvenlik sistemleri, üretim alanlarını en verimli şekilde kullanmak isteyen tesis müdürleri için büyük bir fark yaratır.

Esnek Entegrasyon için Kablosuz NC/NO Temas Sistemleri

Kablosuz NC/NO kontak sistemleri, güvenlik kenar anahtarları için daha önce gerekli olan tüm kabloları ortadan kaldırarak kurulumların nasıl yapıldığını değiştirmektedir. Bu, kurulumun daha basit hale geldiği ve ileride bir şeyin onarılması gerektiğinde daha az zaman ve maliyetle çözülebileceği anlamına gelir. Tasarım esnekliği sayesinde bu sistemler, eski kurulumlara fazla zorlanmadan entegre edilebilir. Özellikle fabrikalar ve üretim tesisleri, üretim ihtiyaçları zamanla değiştiği için bu sistemlerden büyük ölçüde faydalanır. Bugün piyasada mevcut olan seçenekleri görmek isteyenler için EMX Industries'ın WEL-200 modeli, birçok tesisin yakın zamanda benimsediği bir modeldir.

Kapılara ve Kapılara Özel Ağır Ekipmanlı Endüstriyel Modeller

Ağır yük durumları ile uğraşırken, örneğin fabrika girişlerindeki devasa kapılar ya da sürekli açılıp kapanma döngülerine dayanmak zorunda olan depolardaki büyük raylı kapılar gibi uygulamalarda, sanayi sınıfı modeller mutlaka gereklidir. Bu cihazlar, zorlu koşullara ve sürekli kullanım sürecine dayanacak şekilde sağlam yapılmıştır; aşırı hava koşulları ya da yoğun kullanım fark etmeksizin, karşılaştığı her tür zorlukla başa çıkabilecek dayanıklılığa sahiptir. Bu modellerin değerli kılmasının nedeni, özellikle zirve zamanlarda güvenliği riske atmadan tesislerin kesintisiz çalışmasını sağlamasıdır. Tesis yöneticileri bunu çok iyi bilir çünkü kesinti maliyetler anlamına gelir ve çalışanların dışarıda kilitlenmesi ya da ucuz malzemelerin strese dayanamayıp sıkışması sonucu sevkiyat kamyonlarının beklemeye mahkum kalması kimsenin isteyeceği bir durum değildir.

Kurulum En İyi Uygulamaları ve Yapılandırma

Güvenilir Etkinleştirme İçin Doğru Hizalama Teknikleri

Güvenlik kenar sistemlerinin güvenilir bir şekilde çalıştırılması, doğru hizalama ile başlar. Bu sistemler uygun şekilde hizalandığında engelleri daha iyi tespit edebilir ve kazaların oluşmasını engellemek için daha hızlı tepki verebilir. Bakım uzmanlarının çoğu, hizalamayı birkaç ayda bir görsel olarak kontrol edip gerektiğinde ayarlamalar yapılması konusunda öneri sunar. Bu basit rutin, sistemin çalışması gerektiği halde tepki vermediği sinir bozucu anları önemli ölçüde azaltır. Doğru hizalama sadece çalışanların güvenliğini sağlamakla kalmaz; aynı zamanda bu güvenlik cihazlarının ömrünü uzatır ve performanslarını zamanla artırır. Örneğin otomatik kapıları ele alalım. Sensörler doğru şekilde hizalanmazsa kapı bir engeli tamamen atlayabilir. Ancak doğru konumlandırma ile bir şey çok yaklaştığında kapı hemen geri çekilir, ciddi yaralanmaların oluşmasını önler. Birçok tesis yöneticisi, tesislerindeki hizalama sorunlarını giderdikten sonra kaza oranlarında ciddi düşüşler yaşadığını belirtmiştir.

Kablo Yönetimi ve Sinyal Bütünlüğü: Kablolama Düşünceleri

Güvenlik kenarlarını kurarken iyi bir kablo yönetimi çok önemlidir çünkü sinyallerin açık kalmasını sağlar ve tüm sistemin çalışmasını bozabilecek girişimleri önler. Kabloları düzenlemek ve hem elektriksel gürültüye karşı korumak hem de fiziksel zararlardan korumak amacıyla uygun kablo kanallarının kullanılması mantıklıdır. Tüm bağlantıların sıkı olduğundan emin olmak, arızaları azaltır ve genel olarak daha temiz tesisatlar ortaya çıkarır. Endüstriyel ortamlarda bu ekstra dikkat gereklidir çünkü sürekli çalışan karmaşık makinelerle başa çıkmak zorundadırlar. Fabrika müdürleri, güvenlik kenarları doğru şekilde çalışmadığında üretim hatlarının tamirat bitene kadar durduğunu bizzat bilirler.

Belirli Makinalar İçin Kuvvet Eşiklerini Kalibre Etme

Güvenlik kenarı sistemleri için doğru kuvvet eşiği ayarlarını yapmak, farklı makineler arasında her şeyin düzgün bir şekilde çalışmasını sağlamak açısından oldukça önemlidir. Makineler, engelleri tespit edebilmeleri ama her seferinde küçük bir şey olduğunda devreye girmemeleri için farklı hassasiyet seviyelerine ihtiyaç duyarlar. Bakım ekipleri ayrıca bu ayarları düzenli olarak kontrol etmelidir çünkü yanlış kalibrasyon, ileride sorunlara yol açar ve çalışanların güvenliğini tehlikeye atar. Örneğin büyük endüstriyel presler ile daha küçük montaj hatları arasındaki farka bakalım. Daha ağır makineler, normal titreşimlerden dolayı sürekli durmamaları için kesinlikle daha sert ayarlar gerektirir, ancak hangi ekipmanla uğraşıyor olursak olalım güvenlik standartlarını yine de korumak zorundayız.

Güvenlik Standartlarına ve Sertifikalere Uyum

Kapı Sistemleri için UL325 Gereksinimlerini Anlama

UL325, kapı sistemleri konusunda güvenlik için standart belirler ve kapıların olası tehlikelerden insanları koruyacak önemli testleri geçtiğinden emin olur. Şirketler üretim ve kurulum sırasında bu kurallara uyduklarında kapılar çok daha güvenilir ve kaza riski taşımaz hale gelir. UL325'in neler talep ettiğini bilmek, ilgili tüm tarafların yönetmeliklere uygun hareket etmesini sağlarken, aynı zamanda sistemlerin daha güvenli kurulmasına yardımcı olur çünkü şeylerin yanlış gitme ihtimali azalır. UL325 standartlarının pratikte nasıl uygulandığını görmek isteyenler WEL-200 gibi bu standartlara tamamen uygun ürünler inceleyebilir.

EN ISO 13849-1: Güvenlik Performans Düzeyleri (PL) Açıklaması

EN ISO 13849-1 standardı, otomasyon sistemlerindeki riskleri azaltmak için gerekli olan güvenlik performans seviyelerinin belirlenmesinde bir çerçeve sunar. Uluslararası olarak kabul görmüş bir kriter olarak, kontrol sistemi bileşenleri boyunca hayati güvenlik önlemlerinin nasıl değerlendirileceğini ve uygulanacağını net bir şekilde belirlemektedir. Şirketler farklı pazarlarda geçerli olan küresel güvenlik gereksinimlerini karşılayabilmek için bu standardı kavramak zorundadır. Makinelerin standartta belirtilen güvenlik hedeflerine gerçekten ulaşması durumunda, üreticiler işyerindeki korumayı artırırken aynı zamanda otomatik ekipmanlarla yapılan günlük işlemler sırasında oluşabilecek potansiyel tehlikeleri de azaltabilirler.

Sanayi Ekipmanları İçin Üçüncü Taraf Test Protokolleri

Üçüncü taraf testlerinin yapılması, güvenlik kenar sistemlerinin global standartlara uygunluğunu ve güvenilir çalışıp çalışmadığını denetlemede gerçekten önemlidir. Resmi test kuruluşlarıyla çalışmak, şirketlere işlemlerin nerede yanlış gidebileceğini ya da nerede iyileştirme yapılabileceğini göstererek daha güvenli ürünlerin oluşturulmasına yardımcı olur. Gerçekleştirilen testler, ekipmanların zorlu durumlarda bile düzgün çalıştığını ve tüm gerekli uluslararası güvenlik kurallarına uygunluklarını doğrular. İşletmeler bu kapsamlı değerlendirme sürecini dış uzmanlar aracılığıyla gerçekleştirdiklerinde, endüstriyel ekipmanlarının ne kadar güvenli olduğuna dair çok daha fazla güvende hissederler.

Zirve Güvenilirlilik için Bakım Stratejileri

Güvenlik Bileşenleri İçin Rutin Denetim Listeleri

Düzenli muayene kontrol listeleri oluşturmak, güvenlik kenarlarının güvenilir ve düzgün çalışmasını sağlamak açısından büyük fark yaratır. İyi bir kontrol listesi, normal aşınma ve yıpranma kontrolünden her bir parçanın hâlâ tasarlandığı gibi çalıştığından emin olmaya kadar her şeyi kapsar. Şirketler bu muayeneleri planlandığı şekilde yaptığında, küçük sorunlar güvenlik riski oluşturacak büyük sorunlara dönüşmeden erken tespit edilir. Zamanla her bir komponenti yakından takip etmek, işletmelerin güvenlik sistemlerinin büyük oranda sorunsuz çalışmasını sağlar. Bu yaklaşım, beklenmedik arızaları azaltır ve operasyonların gereksiz kesintilere uğramadan devam etmesini sağlar.

Yaygın Elektrik Sinyal Sorunlarını Giderme

Günlük elektrik sinyal problemlerini nasıl çözeceğinizi bilmek, burada işleri güvenli ve verimli bir şekilde çalıştırmada büyük fark yaratır. Teknisyenler bu sorunları kontrol altına almadan önce erken tespit ettiğinde, ileride ciddi güvenlik risklerinin önüne geçilmiş olur. Bu konularla çalışan çoğu kişi, hangi noktalarda sıkça sorun çıktığını ve hangi çözümlerin gerçekten işe yaradığını öğrenerek saatlerce boşa zaman kaybetmeden hareket eder. Biraz bilgi, fabrikalarda ve tesislerde üretkenliğin ve iş güvenliğinin artırılmasında ciddi farklar yaratabilir. Bu konularda çalışanlarını eğiten firmalar ise zaman içinde hem verimlilik hem de iş güvenliği oranlarında daha iyi sonuçlar elde edebilir.

Ausulema Eline Giren Bileşenler İçin Değişim Aralıkları

Aşınmaya eğilimli parçaların değiştirilmesi için üreticinin önerdiği zaman çizelgelerine uyulması, güvenlik seviyelerinin zaman içinde tutarlı bir şekilde korunmasında büyük bir fark yaratır. Aşınmış parçalar zamanında değiştirildiğinde, özellikle gün boyu sürekli kullanılan ekipmanlarda ciddi güvenlik sorunlarına yol açabilecek sehpaların arızalanması önlenmiş olur. Bu tür düzenli bakım uygulamalarına bağlı kalınmasıyla işletmeler, sistemlerinin daha güvenli ve güvenilir kalmasını sağlayabilir ve aynı zamanda ileride oluşabilecek pahalı onarımlardan kaçınmış olurlar. Çoğu endüstriyel tesis, bu değiştirme programlarına sadık kalmanın sadece iyi bir uygulama değil, aynı zamanda parçaların beklenmedik arızalar olmadan güvenlik spesifikasyonlarına uygun şekilde çalışmaya devam etmesini sağlayarak uzun vadede maliyet tasarrufu sağladığını tecrübeyle öğrenmiştir.

Yeni Nesil Teknolojiler Kenar Güvenlik Sistemlerinde

Uzaktan İzleme Yeteneğine Sahip IoT Etkin Anahtarlar

IoT teknolojisi üzerinden bağlanan akıllı anahtarlar, endüstriyel işlemlerin kenarlarında güvenlikle ilgilenme biçimimizi değiştiriyor. Gerçek zamanlı veriler sunarak sorunların oluştuğu anda müdahale edilmesine olanak tanıyor. Bu bağlantılı sistem, işyerinde çalışanların olası sorunlarla ilgili, şeyler kötüye gitmeden çok önce uyarı almasını sağlayarak işyerlerini genel olarak daha güvenli hale getiriyor. Uzaktan izleme özellikleri sayesinde fabrika müdürleri, potansiyel riskli noktaları hızlıca fark edip üretim durmaları veya kaza riskleri olmadan müdahale edebiliyorlar. Birçok fabrika için bu tür bir erken uyarı sistemi vazgeçilmez hale gelmiş. Küçük sorunların, ileride daha büyük sorunlara dönüşmesini engelleyerek hem maddi kayıpları hem de olası can kayıplarını önüyor.

Tanısal Özelliklerle Otamatik Test Eden Güvenlik Kenarları

Kendini test eden emniyet kenarları, her şeyin doğru çalıştığından emin olmak için düzenli kontroller yapan akıllı bir gelişmedir. Bu teknoloji, temelde gün boyu kendini izler ve operatörlere aniden bir şeyin arızalanma ihtimalini azaltarak ekstra güven sağlar. Bu otomatik testler düzenli olarak gerçekleştiğinde, makineler daha uzun süre sorunsuz çalışır ve aniden arıza yapma kaygısıyla uğraşmak zorunda kalınmaz. Özellikle üretim süreçlerinde zaman önemli olduğunda, fabrikalar bu tür güvenilirliği çok önemser. Güvenlik yönetmelikleri ve sıkı teslim tarihleriyle çalışan üreticiler için, performans seviyesini sürekli koruyabilen ekipmanlar, sorunsuz bir operasyon ile maliyetli kesintiler arasında fark yaratır.

Tahmine Dayalı Bakım için Makine Öğrenimi Entegrasyonu

Makine öğrenimini uç güvenlik sistemlerine sokmak, öngörüsel bakım hakkında düşüncelerimizi tamamen değiştiriyor. Bu akıllı algoritmalar fabrika katındaki makinelerden gelen her türlü operasyonel verilere bakıyor, bir şeyin yanlış gidebileceğine dair işaretleri, aslında gerçekleşmeden çok önce tespit ediyorlar. Bu, bakım ekibinin arızaları beklemek yerine sorunları uygun olduğunda düzeltebileceği anlamına geliyor. Şirketler acil onarımlarda tasarruf ederken, işçiler daha güvenli kalır çünkü tehlikeli durumlar erken ele alınır. Gerçek değer, her şeyin çoğu zaman sorunsuz çalışmasını sağlamakla gelir. Fabrikalar artık beklenmedik şekilde kapanmıyor, üretim hatları kesintisiz hareket ediyor ve kritik üretim süreçlerinde kimsenin beklenmedik bir şekilde yakalanmaması, bu süreçte duraklama milyonlara mal oluyor.

SSS

Güvenlik kenar sistemleri ne için kullanılır?

Güvenlik kenar sistemleri, baskıyı veya teması algılamak ve kazaları ve yaralanmaları önlemek amacıyla işlemlerden hızlı bir şekilde durdurmak için otomatikleştirilmiş ortamlarda kullanılır.

Güvenlik kenarları için yanıt zamanı neden kritiktir?

Güvenlik kenarlarının yanıt süresi, özellikle hızlı hareket eden makinelerde kazaların etkisini azaltmada kritik öneme sahiptir ve hızlı ve etkili acil durum yanıtını sağlar.

Bir güvenlik kenarı anahtarı seçerken dikkate alınması gereken faktörler nelerdir?

Uygulamanız için bir güvenlik kenarı anahtarı seçerken çevresel koşulları, güç duyarlılığı gereksinimlerini, malzeme dayanıklılığını ve işletimsel ihtiyaçları göz önünde bulundurun.

IoT destekli anahtarlar, kenar güvenliği sistemlerine nasıl fayda sağlar?

IoT destekli anahtarlar, kazaları önlemeye ve sürekli işlemi sağlamak için kenar güvenliği sistemlerini gerçek zamanlı izleme ve uzaktan sorun giderme yetenekleriyle artırır.

İçindekiler

- Anlayış Güvenlik Kenar Anahtarı İşlevsellik

- Mükemmel Performans için Kritik Seçim Faktörleri

- Güvenlik Kenar Anahtarlarının Türleri ve Kullanım Durumları

- Kurulum En İyi Uygulamaları ve Yapılandırma

- Güvenlik Standartlarına ve Sertifikalere Uyum

- Zirve Güvenilirlilik için Bakım Stratejileri

- Yeni Nesil Teknolojiler Kenar Güvenlik Sistemlerinde

- SSS