Industrial environments present numerous hazards that require robust safety measures to protect workers and equipment. Among the most critical safety components are safety edge switches, which serve as the first line of defense against crushing injuries and equipment damage. These specialized sensors detect contact or pressure along edges of moving machinery, automatically triggering shutdown procedures when potential hazards are identified. Safety edge switches have become indispensable in modern industrial facilities, providing reliable protection across diverse applications from automated doors to robotic systems.

The implementation of safety edge switches significantly reduces workplace accidents while maintaining operational efficiency. These devices integrate seamlessly into existing systems, offering continuous monitoring without disrupting normal operations. Modern safety edge switches feature advanced technology that distinguishes between intentional contact and accidental interference, minimizing false alarms while maximizing protection. Understanding the benefits and applications of safety edge switches is essential for facility managers seeking to enhance workplace safety standards.

Understanding Safety Edge Switch Technology

Basic Operating Principles

Safety edge switches operate on fundamental pressure-sensitive technology that detects physical contact along designated safety zones. When an object or person contacts the switch edge, internal mechanisms immediately generate a signal that interrupts power to connected machinery or triggers emergency stop procedures. This instantaneous response capability makes safety edge switches highly effective for preventing crush injuries and equipment damage in industrial settings.

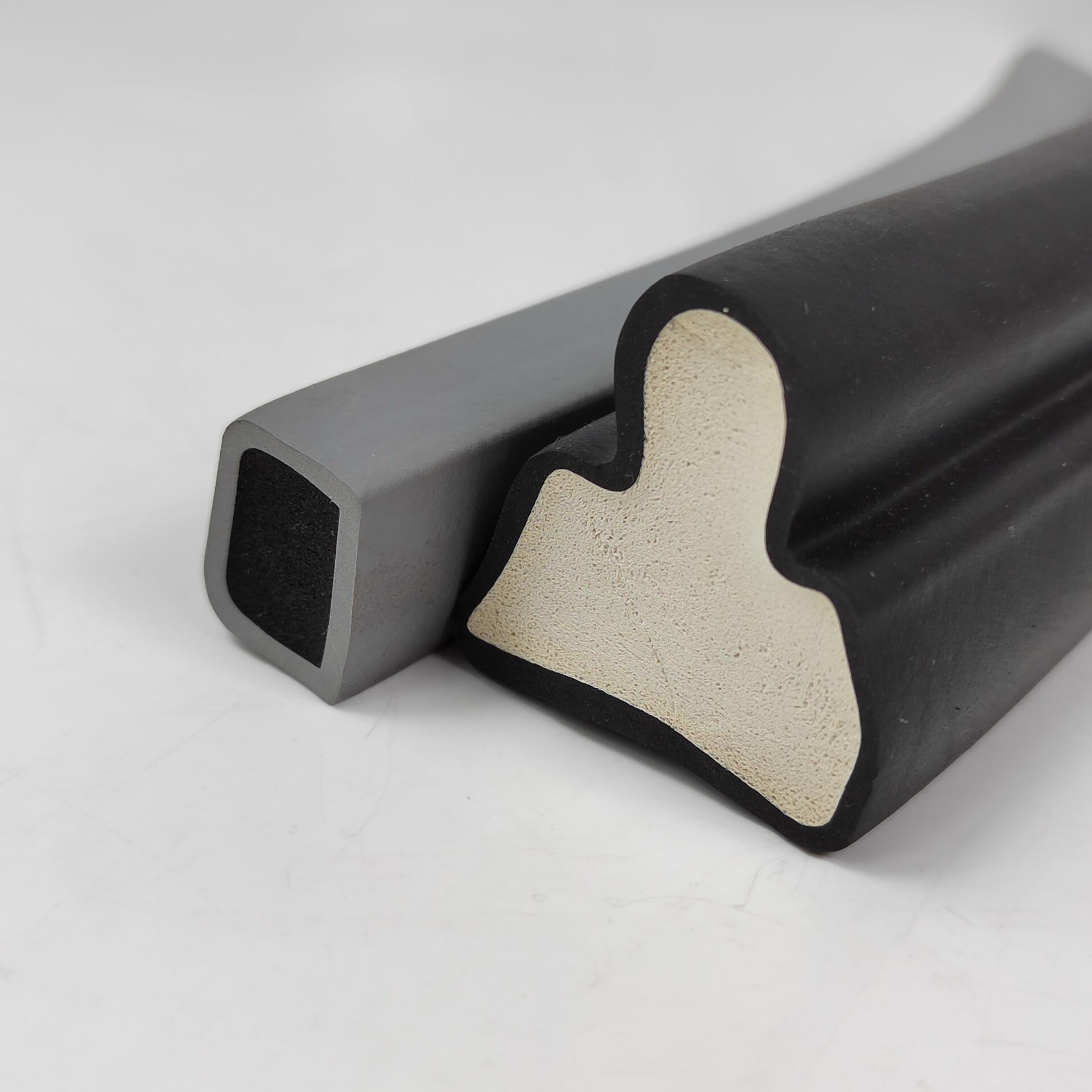

The internal construction of safety edge switches typically includes pressure-sensitive elements housed within durable protective casings. These elements can utilize various detection methods, including mechanical contacts, pneumatic systems, or electronic sensors, depending on the specific application requirements. The reliability of safety edge switches stems from their simple yet robust design, which minimizes potential failure points while maximizing detection sensitivity.

Advanced safety edge switches incorporate multiple redundant systems to ensure fail-safe operation even under extreme conditions. These redundancies include dual-channel monitoring, self-diagnostic capabilities, and tamper-resistant designs that maintain functionality in harsh industrial environments. The combination of proven technology and modern enhancements makes safety edge switches indispensable for comprehensive workplace safety programs.

Integration with Industrial Control Systems

Modern safety edge switches seamlessly integrate with programmable logic controllers and other industrial automation systems through standardized communication protocols. This integration allows for sophisticated safety management that can coordinate multiple protection devices simultaneously while maintaining real-time monitoring capabilities. The ability to connect safety edge switches to centralized control systems enables comprehensive safety oversight across entire facilities.

Integration capabilities extend beyond basic stop functions to include advanced features such as zone-specific responses, graduated safety measures, and predictive maintenance monitoring. Safety edge switches can communicate their operational status, detection events, and diagnostic information to supervisory systems, enabling proactive maintenance scheduling and performance optimization. This connectivity transforms safety edge switches from simple protective devices into integral components of intelligent safety networks.

The standardization of communication protocols ensures that safety edge switches from different manufacturers can work together within unified safety systems. This interoperability provides flexibility in system design and allows for future expansion without requiring complete system overhauls. The result is a scalable safety infrastructure that can adapt to changing operational requirements while maintaining consistent protection standards.

Applications in Industrial Environments

Automated Door and Gate Systems

Automated doors and gates in industrial facilities require reliable safety systems to prevent crushing injuries as these heavy structures move. Safety edge switches mounted along door edges provide immediate detection of obstructions, instantly stopping door movement to prevent accidents. This application is particularly critical in high-traffic areas where workers regularly pass through automated entry points throughout their shifts.

Loading dock doors represent another crucial application where safety edge switches protect both personnel and equipment during freight operations. These doors often handle significant weight and operate in challenging environmental conditions, making robust safety systems essential. Safety edge switches designed for loading dock applications feature enhanced durability and weather resistance to maintain reliable operation despite exposure to temperature extremes, moisture, and debris.

Emergency exit systems also benefit from safety edge switch protection, ensuring that evacuation routes remain clear while providing necessary safety functions during normal operations. The integration of safety edge switches in emergency systems creates dual-purpose protection that enhances both daily safety and emergency preparedness capabilities throughout industrial facilities.

Robotic and Automated Equipment

Industrial robots and automated machinery present unique safety challenges due to their complex movement patterns and significant force capabilities. Safety edge switches installed on robot arms, conveyor systems, and automated guided vehicles provide essential protection by detecting unexpected contact during normal operations. This protection is particularly important in collaborative work environments where humans and robots operate in close proximity.

Manufacturing assembly lines utilize safety edge switches to protect workers who interact with automated equipment during production processes. These applications require highly sensitive detection capabilities to distinguish between normal operational contact and potentially dangerous situations. Safety edge switches in manufacturing environments must maintain consistent performance despite exposure to industrial chemicals, lubricants, and other harsh substances common in production facilities.

Material handling equipment, including automated cranes and lifting systems, relies on safety edge switches to prevent accidents during load movement operations. The positioning of safety edge switches on lifting equipment requires careful consideration of load dynamics and operational requirements to ensure comprehensive protection without interfering with normal functions. Properly implemented safety edge switches in material handling applications significantly reduce the risk of crushing injuries and equipment damage.

Safety Benefits and Risk Reduction

Preventing Crushing and Impact Injuries

The primary safety benefit of safety edge switches lies in their ability to prevent crushing injuries by immediately stopping dangerous machinery when contact is detected. These devices respond faster than human reflexes, providing protection that cannot be achieved through training or procedural controls alone. The instantaneous response of safety edge switches creates a reliable safety barrier that operates independently of human awareness or intervention.

Statistical analysis of workplace accidents shows significant reductions in injury rates when safety edge switches are properly implemented in industrial environments. The most dramatic improvements occur in facilities with heavy machinery, automated doors, and robotic systems where crushing hazards are most prevalent. Safety edge switches not only prevent injuries but also reduce the severity of accidents that do occur by minimizing contact forces and exposure times.

Beyond immediate injury prevention, safety edge switches contribute to long-term worker confidence and productivity by creating demonstrably safer work environments. Workers who trust their safety systems are more likely to focus on their tasks rather than constantly monitoring for potential hazards. This psychological benefit translates into improved work quality, reduced stress-related issues, and enhanced overall workplace satisfaction.

Equipment Protection and Operational Continuity

Safety edge switches protect valuable industrial equipment from damage caused by collisions, overloads, and improper operations. By detecting contact before significant forces develop, these devices prevent costly damage to machinery, tooling, and finished products. The economic benefits of equipment protection often justify safety edge switch investments through reduced maintenance costs and improved operational reliability.

Operational continuity benefits from safety edge switches include reduced downtime due to accidents, fewer emergency repairs, and more predictable maintenance schedules. When safety edge switches prevent accidents, they eliminate the cascading effects of equipment damage, production delays, and regulatory investigations that often follow workplace incidents. This protection helps maintain consistent production schedules and delivery commitments.

The implementation of safety edge switches demonstrates proactive safety management that can positively influence insurance premiums, regulatory compliance ratings, and customer confidence. Many industrial customers now require comprehensive safety systems as conditions for business relationships, making safety edge switches essential for maintaining competitive market positions.

Installation and Maintenance Considerations

Proper Installation Techniques

Successful safety edge switch installation requires careful planning to ensure optimal placement, secure mounting, and proper integration with existing safety systems. Installation teams must consider operational requirements, environmental conditions, and maintenance accessibility when positioning safety edge switches. Proper installation techniques include secure mechanical mounting, appropriate electrical connections, and comprehensive testing to verify correct operation before system activation.

Environmental protection during installation involves selecting appropriate safety edge switches for specific operating conditions and providing additional protection where necessary. Factors such as temperature extremes, chemical exposure, moisture levels, and mechanical vibration must be addressed through proper device selection and protective measures. Installation quality directly impacts long-term reliability and safety performance of safety edge switches throughout their operational life.

Integration testing during installation ensures that safety edge switches function correctly within the broader safety system architecture. This testing includes verification of response times, signal integrity, fail-safe operation, and coordination with other safety devices. Comprehensive installation testing establishes baseline performance parameters that support ongoing maintenance and troubleshooting activities.

Preventive Maintenance Programs

Effective preventive maintenance programs for safety edge switches include regular inspection schedules, performance testing procedures, and systematic replacement protocols. Maintenance activities focus on ensuring consistent sensitivity, verifying electrical connections, and checking for physical damage that could compromise safety performance. Regular maintenance helps identify potential issues before they affect system reliability or safety effectiveness.

Documentation requirements for safety edge switches maintenance include detailed records of inspection results, test procedures, and any corrective actions performed. These records support regulatory compliance efforts and provide valuable data for optimizing maintenance schedules and identifying recurring issues. Proper documentation also facilitates troubleshooting and supports warranty claims when equipment problems occur.

Training programs for maintenance personnel must cover proper testing procedures, safety protocols, and troubleshooting techniques specific to safety edge switches. Well-trained maintenance teams can identify subtle performance changes that might indicate developing problems, enabling proactive repairs that prevent safety system failures. Regular training updates ensure that maintenance practices keep pace with evolving technology and regulatory requirements.

Regulatory Compliance and Standards

Industry Safety Standards

Safety edge switches must comply with various industry standards that govern their design, performance, and application in industrial environments. These standards include specifications for response times, force requirements, environmental ratings, and fail-safe operation that ensure consistent safety performance across different applications. Compliance with recognized standards provides assurance that safety edge switches will perform as expected in critical safety applications.

International standards organizations have developed comprehensive requirements for safety edge switches that address both technical performance and application-specific considerations. These standards cover topics such as electrical safety, mechanical durability, environmental resistance, and integration requirements that guide manufacturers and users in proper implementation. Understanding applicable standards is essential for selecting appropriate safety edge switches and ensuring compliant installations.

Certification programs verify that safety edge switches meet applicable standards through independent testing and evaluation. Certified devices provide documented assurance of compliance that supports regulatory approval processes and demonstrates due diligence in safety system selection. The use of certified safety edge switches can significantly simplify compliance efforts and reduce liability exposure for industrial facilities.

Documentation and Audit Requirements

Regulatory compliance for safety edge switches requires comprehensive documentation that demonstrates proper selection, installation, testing, and maintenance of these critical safety devices. Documentation requirements typically include specifications, installation records, test results, maintenance logs, and incident reports that provide complete traceability of safety system performance. Proper documentation supports regulatory inspections and provides evidence of compliance with applicable safety requirements.

Audit procedures for safety edge switches focus on verifying that installed systems meet design specifications, operate correctly, and receive appropriate maintenance attention. Auditors examine documentation, observe testing procedures, and may perform independent verification of safety system performance. Regular internal audits help identify compliance gaps and ensure that safety edge switches continue to meet regulatory requirements throughout their operational life.

Risk assessment documentation must demonstrate that safety edge switches provide adequate protection for identified hazards and that their implementation follows established safety management principles. This documentation supports the overall safety case for industrial operations and provides justification for specific safety system designs. Thorough risk assessments also help optimize safety edge switch placement and configuration to maximize protection effectiveness.

FAQ

How do safety edge switches differ from other safety devices in industrial environments

Safety edge switches provide contact-based protection specifically along edges of moving equipment, while other safety devices like light curtains use optical beams and pressure mats detect floor-based contact. The key advantage of safety edge switches is their ability to detect contact at the exact point where crushing hazards exist, providing more precise protection than area-based safety systems. They also function effectively in environments where dust, steam, or other contaminants might interfere with optical safety devices, making them particularly suitable for harsh industrial conditions.

What maintenance intervals are recommended for safety edge switches in industrial applications

Most manufacturers recommend monthly visual inspections and quarterly functional testing for safety edge switches in standard industrial environments. However, applications involving heavy usage, harsh conditions, or critical safety requirements may need more frequent maintenance intervals. The specific maintenance schedule should be based on manufacturer recommendations, operational conditions, regulatory requirements, and historical performance data. Regular maintenance helps ensure reliable operation and can prevent safety system failures that might compromise worker protection or operational continuity.

Can safety edge switches be retrofitted to existing industrial equipment

Yes, safety edge switches can typically be retrofitted to existing industrial equipment, though the complexity and cost depend on the specific application and equipment design. Successful retrofitting requires careful evaluation of mounting options, electrical integration requirements, and potential modifications to control systems. Professional installation is recommended to ensure proper integration and compliance with safety standards. Retrofitting safety edge switches to older equipment can significantly improve safety performance and may be required to meet current regulatory standards.

What environmental factors affect safety edge switch performance and selection

Environmental factors that significantly impact safety edge switches include temperature extremes, moisture exposure, chemical contamination, mechanical vibration, and electromagnetic interference. These conditions affect both the selection of appropriate devices and their long-term reliability in industrial applications. Safety edge switches designed for harsh environments feature enhanced sealing, corrosion-resistant materials, and robust construction that maintains performance despite challenging conditions. Proper environmental assessment during selection helps ensure that chosen safety edge switches will provide reliable protection throughout their expected service life.

Table of Contents

- Understanding Safety Edge Switch Technology

- Applications in Industrial Environments

- Safety Benefits and Risk Reduction

- Installation and Maintenance Considerations

- Regulatory Compliance and Standards

-

FAQ

- How do safety edge switches differ from other safety devices in industrial environments

- What maintenance intervals are recommended for safety edge switches in industrial applications

- Can safety edge switches be retrofitted to existing industrial equipment

- What environmental factors affect safety edge switch performance and selection