Tugann timpeallachtaí industrialacha go leor bacadh ar aghaidh a dhéanann torthaí slándála láidir de dhíth chun oibrithe agus innealtóireacht a chosaint. Ar cheann de na comhpháirteanna slándála is mó tá switcháin i mbos na slinn, a úsáidtear mar líne chosanta chéad chun ligheamh do scriosta ó bhruiteadh agus do innealtóireacht. Aithníonn na sainshonraí speisialta seo teagmháil nó brú ar lár na mbearna in innealtóireacht ag bogadh, ag cur críochnaithe go huathoibríoch i ngníomh nuair a aithnítear bacadh. Tá switcháin i mbos na slinn tar éis bheith indispensibtháilte i dteachnaíochtí industrialacha nua-aimseartha, ag soláthar cosaint oiriúnach ar fud feidhmeanna éagsúla ó dhoir ghníomhacha go córais róbótacha.

Tugann an chur i bhfeidhm ar ghlacadáin coisne slándáite laghdú suntasach ar thréimhsí oibre, agus é a dhéanamh gan éifeachtlacht oibriúcháin a mhaolú. Cuireann na gluaisteáin seo isteach go neamhleá i dtsistéimí reatha, ag tabhairt fardorálacha leanúnacha gan obair laistigh den tógalaí a chur as comhtháthú. Tá teicneolaíocht chrua-ghnéithe le fáil ar ghlacadáin coisne slándáite nua-aimseartha, a dhéanann cinneadh idir theagmháil thaitneamhach agus bacadh thar thoirbhearta, ag laghdú a fháil ar allraí míchearta agus ag méadú ar an mbabhta cosanta. Tá sé ríthábhachtach do bhainistírí ionad a thuiscint a fháil ar bhuntáistí agus ar úsáid na gcluasaime coisne slándáite chun caighdeáin slándála ag an áit oibre a fheabhsú.

Tuiscint Spínéad Críoch Scáthán TEICNEOLAÍOCHT

Prinsímaí Oibre Saincheaptha

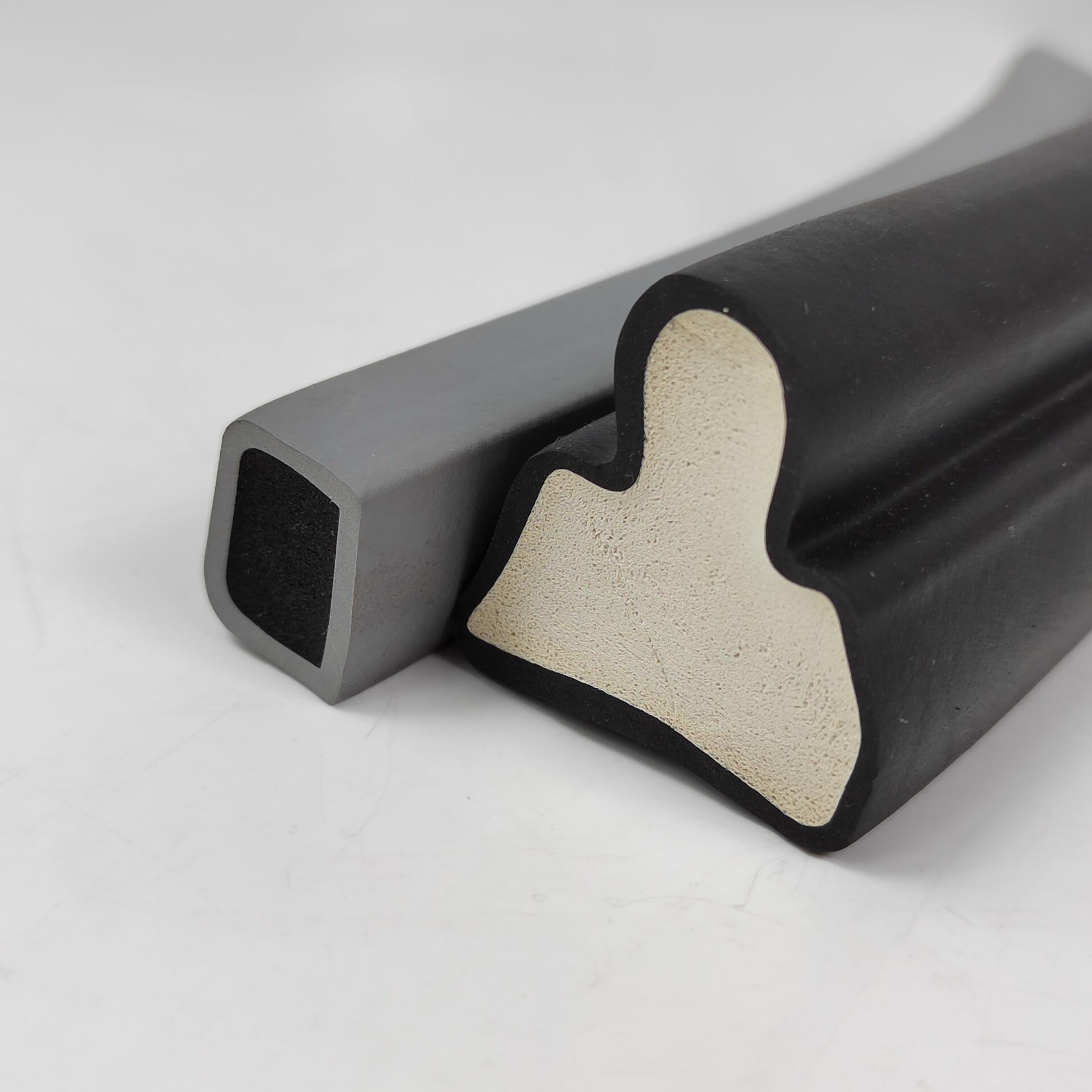

Oibríonn forlíontóirí iomairt slándála ar theicneolaíocht bhunúsach íogaire brú a aimsíonn teagmháil fhisiciúil gar do chonrathanna slándála sainithe. Nuair a théann rud nó duine i dteagmháil leis an mbord iompair, cruthaíonn meicníceacha inmheánacha comhartha láithreach a mhíchumasúcháin cumhacht ar na gluaisteáin nasctha nó a ghríosann próisis stopadh éigeandála. Déanann an uimhirghabháil láithreach seo forlíontóirí iompair slándála thar barr éifeachtach chun dochar imscrúdaithe agus dochar don innealtas a chosc i ngnéithe tionsclaíochta.

De ghnáth cuimsíonn an fhorgnú intinneach ar líontóirí iompair slándála comhpháirteanna íogair ar bhrú curtha laistigh de chasaid chosanta indéanta. Is féidir leis na comhpháirteanna seo úsáid a bhaint as modhanna éagsúla loingseoireachta, lena n-áirítear teagmhála meicniúla, córais phneimiteacha, nó sonraíochtaí leictreonacha, ag brath ar riachtanais an iarratais ar leith. Tá fiordheimhneacht na líontóirí iompair slándála bunaithe ar a ndearcadh shimplí ach láidir, a laghdaíonn pointí neamhbhuantha féideartha agus méadaíonn íogaireacht loingseoireachta go dtí an buaic.

Cuimsíonn scithe críche slándála ar chumas ard chóras iolracha neamhspleáide chun oibríocht shaor ó earráidí a chinntiú fiú faoi shondais éigeandála. Áirítear ar na córais seo monatóireacht dhá chanal, cumais féinfhaghálacha, agus dearadh ina bhfuil sé deacair iad a mhilleadh, go léir atá in ann feidhmniú a choinneáil i gcomhshaoil tionsclaíochta géarchéime. Déanann an comhthreomhadh idir teicneolaíocht bhainte amach agus nuashonraithe nuaime a dhéanamh d’scithe críche slándála gan leithdhóigh do phrógraimí slándála poiblí iomlána.

Comhthéacsú le Scagaire Stiúrtha

Comhlánnaíonn scithe slándála nua-aimseartha go glan le rialaitheoirí loighcicléirithe agus córais eile uathoibriúcháin tionsclaíoch trí choirnéil cumarsáide caighdeánta. Ligeann an comhphósáil seo le bheith ag bainistiú slándála casta a chomhaordáil go comhthreomhar ar roinnt gléasanna cosc, agus ag an am céanna feidhmiúlacht mionn-eolas i ndáiríre a choimeád. Cuireann an cumas nascadh scithe críche slándála le córais rialaithe lárnacha cinnteacht iomlán ar shlándáil ar fud ionad iomláin ar fáil.

Leathann teorainneacha na gcomhtháiteachtaí thar fhorcanna stopa bunscoile chun gnéithe casta a áirithint ar nós freagrachtaí ar bhonn réigiún, tomhaiseanna slándála céime, agus monatóireacht cothabhála réamhchóirithe. Is féidir le sleamhnáin ísle slándála cumarsáid a dhéanamh faoin staid oibre, imeachtaí a bhrath, agus faisnéis dhiagnóiseach chuig córais fhóirneoir, rud a cheadaíonn scéimeáil chothabhála roimh ré agus uasmhéadrú feidhmíochta. Tugann an nascán seo sleamhnáin ísle slándála ó dhífhabhraic amháin go comhpháirtí bunúsacha de líonraí slándála intleachtúla.

Déantar caighdeánúchán prótacal cumarsáide a chinntiú go bhféadfaidh sleamhnáin ísle slándála ó thaoirseoláirí éagsúla oibriú le chéile laistigh de chórais slándála aontaithe. Soláthraíonn an idirdhéanachas seo fleacsacht i ndearadh chórais agus ceadaíonn sé le forbairt amach anseo gan go mbeadh riachtanas le athchóiriú iomlán an chórais. Torthas is ea infrastruchtúr slándála scáláilte a fhéadfaidh sáinniú do riachtanais oibre atógtha agus cothú caighdeán cosanta leanúnach.

Úsáid Bhfianaise sa mballstáit íoctha

Córais Dorchla agus Geata Uathoibríocha

Teastaíonn córais sábháilteachta éifeachtacha ó dhoras agus geataí uathoibríocha i ngnólachtais chun dochar a dhéanamh ar dhuine a sheachaint nuair a bhíonn na struchtúir seo tromsa ag gluaiseacht. Soláthraíonn sleamhnáin sábháilteachta suiteáilte faoi leac na dorois deteagtha láithreach de bhriseadh, ag stopadh an ghluaisimh dorus láithreach chun tionscadail a sheachaint. Tá an fheidhm seo faoi leith thar a bheith tábhachtach i réigiúin ard-eolais áit a mbíonn oibrithe ag pasáil go rialta trí phointí ionntrála uathoibríocha le linn a gcónaí.

Doras tobar luchtaithe is eile feidhm thábhachtach atá ann ina mbaineann sleamhnáin sábháilteachta cosaint do dhaoine agus do mhoncaíochtaí le linn oibríochtaí tráchtála. Bíonn casta mór orthu go minic agus oibríonn siad i dtíomóintí dúshlánaí, rud a fhágann go bhfuil buntaobh sábháilteachta neamhspleách riachtanach. Tá néalaíocht ard agus neart in aer amháin ar sleamhnáin sábháilteachta deartha do fheidhmeanna tobar luchtaithe chun oibriú éifeachtach a choimeád fiú faoi dhrochshuíomh teasa, salainne agus salachair.

Bainfidh córais scoirteanna eisiata o chosaint ó ghléasraí comhaireamh slíochta, ag cinntiú go mbíonn na bealaí frithshcoirteála soiléir agus go mbeidh foinseachtaí slándála riachtanacha ar fáil le linn oibríochtaí gnáthshláintiúil. Tugann an comhionannú spéisanna sláinte isteach i gcórais eisiata cosaint dhá thógál a mhéadaíonn cumais slándála laethúla agus réidheacht do thionscalacha tionscail i gcoitinne.

Robóit agus Uirlisí Uathoibríocha

Tugann roinnt dúshláin uathrialacha le roinnt uirlisí tionscail agus le uirlisí uathoibríocha mar gheall ar na patrúin imoibrithe casta agus na cumanna suntasacha atá acu. Soláthraíonn gléasraí comhaireamh slíochta ar mhéara roinnt, córasraim shiombair agus iarrachtaí treoraithe uathoibríocha cosaint bhunúsach trí théagmháil easpóite a bhrath le linn oibríochtaí gnáthshláintiúla. Tá an chosaint seo faoi leith tábhachtach i gcomhshaol oibre comhoibriúil áit a oibríonn daoine agus roinnt in aice dá chéile.

Úsáideann línte monaróireachta slisní sábháilteachta chun oibrithe a bhfuil baint acu le hionstraim uathoibríocha le linn próiseas táirgeachta a chosaint. Teastaíonn cumais dalghearrtha an-fhairsing chun teagmháil rialta ón gceart a dhéanamh idir theagmháil rialta agus staid amhrasacha nó contúirteacha. Caithfidh slisní sábháilteachta i ngnéithe tháirgeála feidhmniúcht beocht a choimeád fiú amháin faoi dhroch-ghnéithe cosúil le ceimiceáin induistriúla, ionduil agus ábhair chrua eile atá coitianta i dteachanna táirgeachta.

Baineadh úsáid as uirlisí láimhseála míre, lena n-áirítear crainn uathoibríocha agus córas íslaithe, le sleamhnáin sábháilteachta chun beochana a choinneáil ar bunrúcháin le linn oibríochtaí bogadh lucht. Teastaíonn smaoineamh cúramach ar shuíomh na sleamhnán sábháilteachta ar an bhfaisnéis íslaithe chun dinimicíocht an luchta agus riachtanais oibre a chur san áireamh ionas go mbaineann cosaint iomlán gan cur isteach ar oibríochtaí gnáth. Laghdaíonn sleamhnáin sábháilteachta cuí i bhfeidhmíochtaí láimhseála míre an riosca de ghortuithe brúite agus damáiste don eispéireas go mór.

Sochair Shábháilteachta agus Laghdú Ar Riosca

Cosc ar Ghortuithe Brúite agus Bualadh

Is é an buntáiste slándála príomha a bhaineann le sleamhnáin crinne slándála ná a gcumas dochar cruinnithe a chosc trí mheaisíní contúirteacha a chur in ceal láithreach nuair a fhaightear teagmháil. Freagairt na gléasanna seo níos tapúla ná imshionnais dhaoine, ag soláthar cosaint nach bhféidir a bhaint amach trí iarratas nó smachtóireacht phróiseála ar aghaidh féin. Cruthaíonn an freagaireacht láithreach sleamhnán crinne slándála bac slándála oibleáideach a oibríonn neamhspleách ar aitheantas nó intervention duine.

Taispeánann anailís staitistiúil beochana sa chóras laghdú suntasach i rátaí dochar nuair a chuirtear sleamhnáin crinne slándála i bhfeidhm go beacht i gcomhthéacsanna tionsclaíocha. Bíonn na feabhsuithe is mó ar siúl i dteachnaí le meaisíní trom, dorus uathoibrithe, agus córais róbótacha áit a bhfuil contúirtí cruinnithe is coitianta. Ní ach go cuireann sleamhnáin crinne slándála rogha ar dhochain, ach cuireann siad freisin an dochar a tharlaíonn in ísliú trí na hfhórsaí teagmhála agus ama nochtúcháin a laghdú.

Chomh maith le forbairt ionsaíocha láithreach, cuireann sleamhnáin slinn slándála cúram ar thionchar fadtéarmach ar chonspóid an oibre agus ar tháirgeadh trí thógáil timpeallachta oibre atá soiléir go bhfuil sé slán. Is fiúntach do na hoibrithe a chreideann i gcórais a slándála bheith níos mó ag díscaoileadh ar a n-ascach seachas ag faire go leanúnach ar dhrochshaol. Tionchair an tsochar síceolaíoch seo ar ardaithe ar cháilíocht na hoibre, laghdú ar cheist chomhcheangailte le streis, agus feabhsú ar thiomantas an phoist san áit oibre.

Cosaint Uirlisí agus Leanúint Oibre

Cuireann sleamhnáin slinn slándála cosaint ar uirlisí tionsclaíocha luachmhar ó phian dá bharr colaidhm, forluchta, agus oibríochta mícheart. Trí théamh a aimsiú sula dtugtar cumhacht mhór, cuireann na gluaisteáin seo cosc ar phian daor le meaisíní, uirlisí, agus táirgí críochnaithe. Mar thoradh airgeadaisigh ar chosaint uirlisí, minice a mhaithíonn sé infheistíocht i sleamhnáin slinn slándála tríd ghlacadh le costais ísle cothabhála agus feabhas a chur ar dhéinealas oibre.

Cuireann breisbhuntáistí ar leanúint oibre ó ghnéithe slándála leis an éifeacht a bhíonn acu ar laghdú ama in easnamh mar gheall ar thimpistí, laghdú ar réimseadhthí eisiachta, agus scéimeanna cothabhála níos réasúnaithe. Nuair a chuireann gnéithe slándála cosc ar thimpistí, cuireann siad deireadh leis na hathruithe teagmhálacha a bhíonn ann i ndiaidh damáiste don mhaisnéis, mhoill ar tháirgeadh, agus fianóin rialuithe a thagann go minic tar éis imeachtaí sa phost. Cabhraíonn an chosaint seo le scéimeanna táirgeachta leanúnach agus gealltanas soláthairtí a choinneáil.

Tugann forbartha gnéithe slándála léargas ar riarachán slándála imníoch a d'fhéadfadh tionchar dearfach a bheith aige ar shraithscrínní ostaíochta, ar rátaí comhlíonachta rialuithe, agus ar chiontacht na gcustaiméirí. I measc custaiméirí ionsaíocha go fóill, éilíonn go leor córas slándála iomlána mar choinníollacha do dhlíthe gnó, rud a fhágann gur rud riachtanach atá gnéithe slándála chun suíomh margaidh chomptíteacha a choinneáil.

Smaointe maidir le suiteáil agus cothabháil

Tecnicí Fheidhmiúcháin Choinnigh

Teastaíonn plaenáil cúramach chun suiteáil rathúil a dhéanamh ar ghléasraí sábháilteachta cois timpeall, chun áitshuiteáil oiriúnach, socruithe slán, agus comhtháthú ceart le córais shábháilteachta reatha a chinntiú. Caithfidh fhoirne suiteála breathnú ar riachtanais oibre, ar choinníollacha timpeallach, agus ar rochtain do threoraithe nuair a bhítear gléasraí sábháilteachta cois timpeall á bpostáil. Cuimsíonn teicnící chearta suiteála socruithe meicniúla slána, nascanna leictreacha oiriúnacha, agus tástáil iomlánúil chun oibríocht cheart a fhíorú sula gcuirtear an córas i bhfeidhm.

Baineann comhdháil chosanta comhshaoil le roghnú scagaire bearna slándála cuí do chúinsí oibriúcháin ar leith agus soláthar cosaint bhreise nuair a bheidh uainn. Caithfear cúis a bheith againn le hionchúisí cosúil le teochtaí fó, nochtadh do chéimeanna, leibhéil fíochachta agus croith mheicniúil trí roghnú chóir gléasanna agus tomhais chosanta. Tiontann cáilíocht na comhdhála go díreach ar dhéineamh slándála agus ar fhidhlaiseacht an scagaire bearna slándála ar feadh a shaol oibriúcháin.

Déantar tástáil chomhtháiteachta le linn na comhdhála chun cinntiú go n-oibríonn scagairí bearna slándála i gceart laistigh den archatíocht chóras slándála níos leithne. Cuimsíonn an tástáil seo dearbhú ama freagairthe, éifeachtacht shínéil, oibríocht fail-saor agus comhoibriú le gluaisteáin slándála eile. Cruthaíonn tástáil chomhdhála chuimsitheach paramadair bhunúsacha a thacaíonn le gníomhaíochtaí cothabhála agus réitigh fhadhbanna ar leanúint.

Clár Mianta Uchtai

Cláraíonn cláir chosaint éifeachtacha do ghlacadáin coisc slándála scéimeanna rúnscrúdaithe riaghlaithe, prótócaid teastála feidhmíochta, agus prótócaid iondúchta córasach. Bainneann gníomhaíochtaí cosaint le cinntiú a dhéanamh ar mhéid tábhachtúil leanúnach, dearbú ceangaltán leictreacha, agus seiceáil do charthan fhisiciúil a d’fhéadfadh slándáil feidhmíochta a mharú. Cabhraíonn cosaint rialta le dúshláin féideartha a aithint sula mbeidh tionchar orthu ar sholúbthacht an chórais nó ar éifeachtacht na slándála.

Áirítear ar riachtanais doiciméite do chosaint ghlacadáin coisc slándála taifid mhionsonraithe ar thorthaí rúnscrúdaithe, prótócaid teastála, agus aon gníomhartha cheartmhara a rinneadh. Tacaíonn na taifid seo le iarraidh réigiúnálta agus soláthraíonn siad sonraí luachmhar chun scéimeanna cosaint a uasmhéadú agus dúshláin atá ag athrá a aithint. Cuireann doiciméadú ceart boscaireacht i bhfeidhm níos éadroime chomh maith agus tacaíonn sé le iarraidh bharánta nuair a tharlaíonn fadhbanna leis an bhfeidhmeannas.

Caithfidh cláir oiliúna do dhuine a dhéanann cothabháil cúrsaí iomaithe cearta, prótacóil slándála agus teicnící fadhbshloinne a chlúdach a bhaineann go sonrach le sleasáin ionchurtha slándála. Is féidir le fhoirne maoinithe go maith fadhbanna beaga a aithint a d'fhéadfadh tionchar a bheith orthu ar feidhmniúlacht, rud a chumasaíonn deisiúcháin roimh ré a dhéanamh sula mbeidh trioblóidí ar chóras slándála. Bheartaítear nuashonruithe oiliúna go rialta chun cinntiú go mbíonn cleachtais chothabhaíochta suas chun dáta leis an teicneolaíocht agus na riailí atá ag forbairt.

Comhlíonadh Rialacháin agus Caighdeáin

Staidrimh slándála an tionscail

Caithfidh sleasáin ionchurtha slándála comhlíonadh standair éagsúla tionscail a rialaíonn a ndearcadh, a n-innealtóireacht agus a n-úsáid i gcomhthéinnteachtaí tionscalacha. Cuimsíonn na stándair seo sonraí faoi amais freagairthe, riachtanais mhéide, rátaí comhshaoil agus oibríocht gan phroiblem a chinntiú go mbeidh feidhmniúlacht slándála cothrom ar fud úsáidí éagsúla. Soláthraíonn comhlíonadh le stándair a bhfuil aitheantas acu cinnteacht go mbeidh na sleasáin ionchurtha slándála ag feidhmiú mar is iontach i bhfeidhmeanna slándála criticiúla.

Tá riachtanais chuimsitheacha curtha ag eagraíochtaí idirnáisiúnta caighdeán ar ghnéithe slándála a lánann gnéithe teicniúla agus meabhrachtaí ar bhonn sonrach iarratais. Lántar na caighdeáin seo ábhair amhail slándáil leictreach, forbarthacht mheicniúil, fáthúlacht timpeallachta agus riachtanais iontegráide a threorann déantóirí agus úsáideoirí i gcur i bhfeidhm cheart. Tá sé ríthábhachtach tuiscint a fháil ar na caighdeáin atá ábhartha chun gnéithe slándála cuí a roghnú agus cur i bhfeidhm ina dteannta a chinntiú.

Deimhníonn clárainní deimhnithe go mbíonn gnéithe slándála comhdháilte leis na caighdeáin ábhartha trí thástáil agus meastachán neamhspleách. Soláthraíonn gléasanna dearbhaithe deimhniú doiciméadaithe comhlíonadh a thacaíonn le próisis ceadaithe rialuithe agus a léiríonn cúram freagrach i roghnú córas slándála. Is féidir le húsáid gnéithe slándála dearbhaithe comhlíonadh a éascú go mór agus aonmhaireacht a laghdú do cháilíochtacha tionscail.

Riachtanais Doiciméadaithe agus Frithbhacainne

Éilíonn comhlachtúlacht rialacháin do ghléasanna sábháilteachta teorann tráchtúnála iomlán a léiríonn roghnú, suiteáil, tástáil agus cothabháil cheart na gléasanna sábháilteachta criticiúla seo. Áirithí ar riachtanais tráchtúnála de ghnáth sonraíocht, taifid shuiteála, torthaí tástála, logaí cothabhála agus tuairiscí eachtraí a sholáthraíonn traceáiltacht iomlán ar fheidhmneacht an chóras sábháilteachta. Cabhraíonn tráchtúnál ceart le tionscnamh rialachán agus soláthraíonn sé cruthúnas comhlachtúlachta le riachtanais shábháilteachta ábhartha.

Baineann próisis fhianaise do ghléasanna sábháilteachta teorann le dearbhú go mbíonn na córais shuiteáilte comhdháilte le sonraíocht an dhearbhúcháin, go bhfeidhmíonn siad i gceart agus go bhfuil aire chothabhála cuí acu. Scruteálann fianaisitheoirí tráchtúnáil, breathnaíonn siad ar phróisis tástála, agus d'fhéadfadh siad feidhmneacht an chórais sábháilteachta a fhianaiseoireacht neamhsple. Cabhraíonn fianaisí inmheánacha riaghlaithe le gaps comhlachtúlachta a aithint agus le cinntiú go leanann gléasanna sábháilteachta teorann ag comhlachtú le riachtanais rialachán ar feadh a saoil oibre.

Caithfidh cáipéisí meastacháin isteachais a léiriú go mbaineann sleamhnáin críche slándála buntaoise dochar a aithint agus go ndéantar iad de réir prionsabail bhunaithe ar chumarsáid slándála. Tacannaíonn an cháipéis seo leis an gcás slándála ar fad do oibréidh in dustáil agus cuireann sé béim ar dhearbháil ar dhearthóirí áirithe córas slándála. Cabhraíonn meastacháin isteachais chuimsitheach freisin le hathróiptiú a dhéanamh ar shuíomh agus ar chumraíocht sheamhnán críche slándála chun cosaint a uasmhéadrú.

FAQ

Conas a éagsúlann seompraóirí críche slándála ó sheompraóirí slándála eile i gcomhthéisiúin indistriúla

Soláthraíonn scagairí coisc sláinte cosc bunaithe ar theagmhálacha go beacht garbhán na hionramhán ag bogadh, agus úsáideann gléasanna sláinte eile cosúil le cuirtíní solais beamanna optaighleacacha agus fuinneoga brú a bhrath teagmháil ar an urlár. Is é an buntáiste mór le scagairí coisc sláinte ná a gcumas teagmháil a bhrath ag an gcodarsnacht nuair a bhíonn bac ar chor ar bith ann, ag soláthar cosc níos cruinne ná córais sláinte bunaithe ar cheantair. Feidhmíonn siad go maith freisin i gcomhthéacsanna ina bhféadfadh dustáil, steaim nó néaltaigh eile cur isteach ar ghleasanna sláinte optaighleacacha, rud a dhéanann iad go háirithe oiriúnach do choinníollacha tionsclaíochta géarchéime.

Cén tréimhse cothabhála atá moltha do scagairí coisc sláinte i bhfeidhmchláir thionsclaíocha

Moltaíonn formhór na monaróirí iniúchaimh amhairc mhíosúla agus tástáil oibre gach trí mhí do ghléasraí béime slándála i ngnéithe tionsclaíochta caighdeánacha. Fad atá le feiceáil, d'fhéadfadh cur chuige a bhaineann le húsáid trom, coinníollacha géar nó riachtanais shláinteachta meáchanacha dul i bhfeidhm ar thairseachanna oibre níos minice. Ba chóir an scéimre áirithe um chonsairí a bheith bunaithe ar mholtaí na monaróra, ar choiriúilí oibre, ar riachtanais rialaithe agus ar shonraí fairsinge faoi cheannróid cheana féin. Cabhraíonn cónsairí riaghlaithe le cinntiú go rachaidh an córas slándála i bhfeidhm go minic agus go mbeidh sé in ann teip ar chórais slándála a sheachaint, rud a d’fhéadfadh slándáil na n-oibrithe nó leanúint ar aghaidh den obair a mheas.

An féidir gléasraí béime slándála a chur le chuid reoite asraonach ionamhlaíocha

Is féidir leis na sleamhnáin sábháilteachta go minic a bheith inarbhailithe ar mhaisíní tionscail reatha, cé go bhfuil an castacht agus an t-ardán ag brath ar an bhfeidhmniú agus ar dhearthóireacht na mbeart. Teastaíonn meastúnadh cúramach de roghanna suímh, riachtanais le haghaidh comhtháthú leictreach, agus athruithe is dócha ar chórais smaointe chun athshuiteáil rathúil a dhéanamh. Molannar suiteáil ghairmiúil chun cinntiú go mbeidh comhtháthú ceart ann agus comhlíonadh caighdeáin sábháilteachta. Is féidir le hathshuiteáil shleamhnán sábháilteachta ar cheimicí seanda sábháilteacht a fheabhsú go mór, agus d'fhéadfadh gur gá í chun caighdeáin rialaithe reatha a chomhlíonniú.

Cén fhachtóirí timpeallachta a éiríonn tionchair ar fheidhmiú agus roghnú sleamhnán sábháilteachta

Is iad fachtóirí timpeallachta a bhíonn tionchar mór acu ar ghluaisteáin sábháilteachta ná teochtaí extreme, nochtadh don mhais, truailleadh ceimiceach, craos meicniúil, agus bacadh leictreamhgnéasach. Tionchair na coinníollacha sin ar roghnú gluaisteán oiriúnacha agus ar a hinmheáineacht faoi leith i feidhmchórais ionsaíoch. Tá sreaptha sábháilteachta atá deartha do thimpeallachtaí géar le sealálú neartaithe, ábhair ina bhfuil inmheáineacht don chorróid, agus tógáil láidir a chaomhnaíonn feidhmneacht fiú faoi choinníollacha dúshlána. Cabhraíonn seasamh oiriúnach timpeallachta a dhéanamh le linn an roghnúcháin le cinntiú go mbreoitear cosc iontaofa ón gcuid den ghluaisteán sábháilteachta roghnaithe ar feadh a shaol feidhmiúil sultánta.

Clár na nÁbhar

- Tuiscint Spínéad Críoch Scáthán TEICNEOLAÍOCHT

- Úsáid Bhfianaise sa mballstáit íoctha

- Sochair Shábháilteachta agus Laghdú Ar Riosca

- Smaointe maidir le suiteáil agus cothabháil

- Comhlíonadh Rialacháin agus Caighdeáin

-

FAQ

- Conas a éagsúlann seompraóirí críche slándála ó sheompraóirí slándála eile i gcomhthéisiúin indistriúla

- Cén tréimhse cothabhála atá moltha do scagairí coisc sláinte i bhfeidhmchláir thionsclaíocha

- An féidir gléasraí béime slándála a chur le chuid reoite asraonach ionamhlaíocha

- Cén fhachtóirí timpeallachta a éiríonn tionchair ar fheidhmiú agus roghnú sleamhnán sábháilteachta