Industrial facilities face unique challenges when it comes to workplace safety, particularly regarding floor protection and hazard mitigation. Industrial safety floor mats have become essential components in manufacturing plants, warehouses, and heavy machinery operations where worker protection takes priority. These specialized mats serve multiple functions beyond basic comfort, including pressure-sensitive switching, anti-static protection, and signal transmission capabilities that integrate seamlessly with modern industrial safety systems.

The selection of appropriate floor protection systems directly impacts operational efficiency, compliance standards, and overall workplace safety metrics. Understanding the various types of industrial safety floor mats available helps facility managers make informed decisions that align with their specific operational requirements. From basic cushioning solutions to advanced pressure-sensitive safety switches, these protective systems offer diverse functionalities tailored to different industrial environments.

Pressure-Sensitive Safety Mat Systems

Ground-Sensing Technology Integration

Pressure-sensitive industrial safety floor mats represent advanced safety technology designed to detect human presence and automatically trigger safety responses. These mats incorporate sophisticated sensing mechanisms that respond to foot pressure, immediately transmitting signals to connected machinery or safety systems. When workers step onto these mats, the integrated pressure sensors activate safety protocols, such as emergency stops, warning signals, or equipment shutdowns.

The technology behind these systems relies on precise calibration to distinguish between intentional human contact and incidental impacts from dropped objects or equipment vibrations. Modern pressure-sensitive mats utilize multiple sensor zones to provide comprehensive coverage and reduce false activations. The signal transmission capabilities ensure rapid response times, typically within milliseconds of pressure detection, making them ideal for high-risk industrial environments where immediate safety interventions are critical.

Signal Transmission and Control Integration

Advanced industrial safety floor mats feature integrated signal transmission systems that communicate with broader facility safety networks. These mats can interface with programmable logic controllers, emergency stop circuits, and automated safety systems to create comprehensive protection zones. The signal transmission capabilities allow for both wired and wireless connectivity options, providing flexibility in installation and system integration.

The reliability of signal transmission becomes paramount in industrial settings where safety depends on instantaneous communication between floor sensors and control systems. Modern industrial safety floor mats incorporate redundant signal pathways and fault detection mechanisms to ensure continuous operation even under challenging conditions. This technology enables real-time monitoring of mat status, pressure distribution, and system integrity through centralized control interfaces.

Anti-Static Floor Protection Solutions

Static Electricity Mitigation in Sensitive Environments

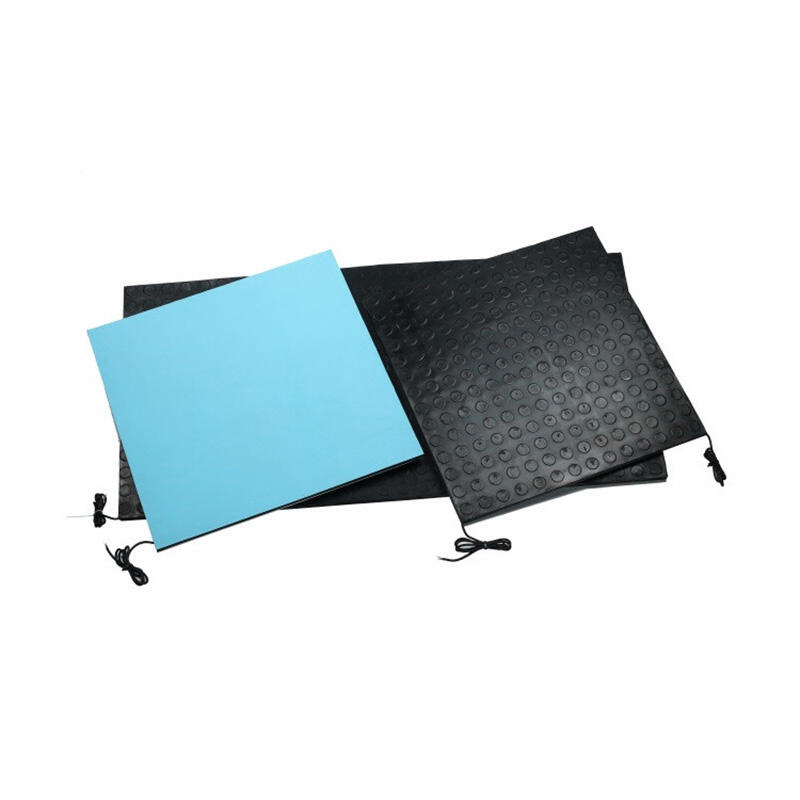

Anti-static industrial safety floor mats address critical concerns in electronics manufacturing, pharmaceutical production, and chemical processing facilities where static electricity poses significant risks. These specialized mats dissipate electrostatic charges safely to ground, preventing dangerous accumulations that could ignite flammable materials or damage sensitive electronic components. The conductive materials integrated into these mats create controlled pathways for static discharge while maintaining safe resistance levels.

The effectiveness of anti-static protection depends on proper grounding systems and regular conductivity testing to ensure consistent performance. These mats typically feature surface resistivity measurements between specific ranges that balance static dissipation with electrical safety. Regular maintenance protocols include conductivity verification, surface cleaning with appropriate solutions, and inspection for wear patterns that might compromise anti-static properties.

Carpet Switch Technology

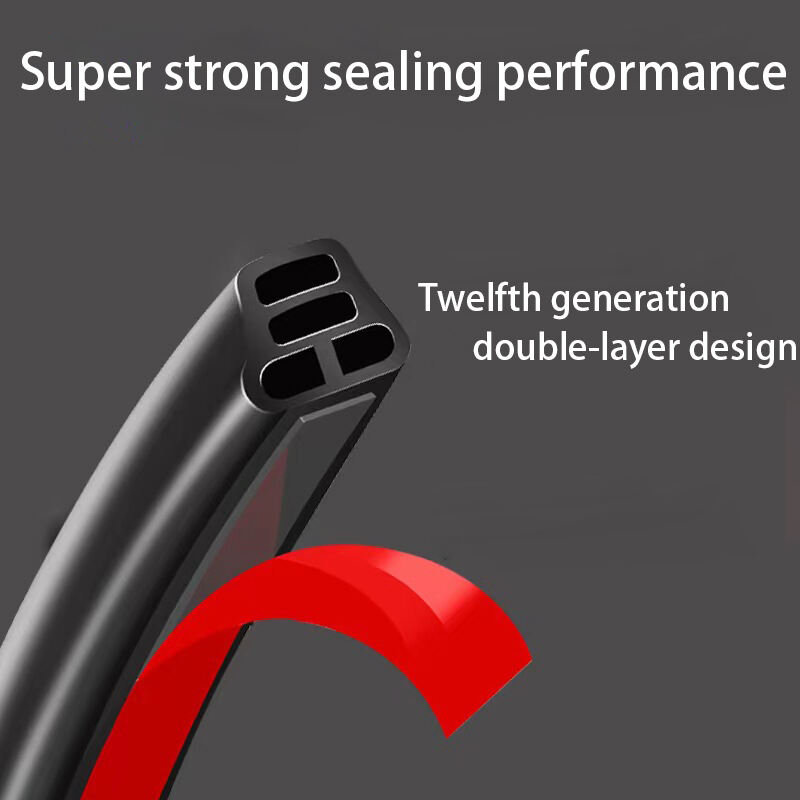

Carpet switch technology represents an innovative approach to integrating safety switching capabilities into comfortable floor coverings. These industrial safety floor mats combine the ergonomic benefits of cushioned surfaces with advanced switching mechanisms that activate when pressure is applied. The carpet-like surface provides comfort for workers who stand for extended periods while maintaining the sensitivity required for reliable safety switching.

The construction of carpet switch mats involves multiple layers that work together to provide both comfort and functionality. The top surface offers traction and comfort, while underlying layers contain the switching mechanisms and signal transmission components. This design allows for easy integration into existing floor systems while providing the durability necessary for industrial environments where heavy foot traffic and equipment movement are common.

Heavy-Duty Industrial Mat Applications

Manufacturing Floor Protection

Manufacturing environments require industrial safety floor mats that can withstand constant exposure to oils, chemicals, and heavy machinery operations. These mats must provide slip resistance, chemical resistance, and durability while maintaining their safety functions over extended service periods. The material selection for manufacturing floor mats typically includes compounds that resist degradation from industrial fluids and maintain structural integrity under mechanical stress.

The design considerations for manufacturing floor protection include drainage systems for liquid management, beveled edges for equipment accessibility, and modular construction for easy replacement of damaged sections. These industrial safety floor mats often incorporate raised surface patterns that enhance traction while facilitating cleaning and maintenance. The ability to customize mat configurations allows manufacturers to address specific workflow patterns and machinery layouts effectively.

Warehouse and Distribution Center Solutions

Warehouse operations present unique challenges for floor protection systems, including high-traffic areas, forklift operations, and varying load distributions. Industrial safety floor mats designed for warehouse applications must balance comfort for workers with durability sufficient to handle material handling equipment. These mats often feature reinforced construction and impact-resistant materials that maintain their protective properties under demanding conditions.

The strategic placement of industrial safety floor mats in warehouse environments focuses on high-risk areas such as loading docks, equipment operation zones, and pedestrian crossings. These locations benefit from enhanced visibility features, including high-contrast colors and reflective elements that improve safety awareness. The modular design of warehouse floor mats enables customization of coverage areas and facilitates maintenance without disrupting operations.

Installation and Maintenance Considerations

Proper Installation Techniques

The effectiveness of industrial safety floor mats depends significantly on proper installation procedures that ensure optimal performance and longevity. Installation requirements vary based on mat type, facility conditions, and integration with existing safety systems. Proper substrate preparation, including surface cleaning, leveling, and moisture control, establishes the foundation for successful mat installation and long-term performance.

Professional installation of pressure-sensitive and signal transmission mats requires careful attention to electrical connections, grounding requirements, and system calibration. The installation process must maintain the integrity of sensing mechanisms while ensuring secure attachment to floor surfaces. Documentation of installation procedures, including wiring diagrams and calibration settings, provides essential reference information for future maintenance and troubleshooting activities.

Preventive Maintenance Programs

Effective maintenance programs for industrial safety floor mats extend service life while ensuring consistent safety performance. Regular inspection schedules should include visual examination for wear patterns, damage, and contamination that might compromise mat effectiveness. Functional testing of pressure-sensitive features and signal transmission capabilities verifies proper operation and identifies potential issues before they affect safety performance.

Cleaning protocols for industrial safety floor mats must balance thorough contamination removal with protection of sensitive components and surface properties. The selection of appropriate cleaning agents and methods depends on mat materials, environmental conditions, and specific contamination types. Maintenance records provide valuable data for optimizing replacement schedules and identifying patterns that might indicate underlying facility issues affecting mat performance.

Compliance and Standards

Industry Safety Regulations

Industrial safety floor mats must comply with various safety standards and regulations that govern workplace protection systems. These standards address material properties, performance requirements, and testing procedures that ensure consistent quality and reliability. Compliance with industry standards provides assurance that mats will perform as expected in critical safety applications and meet the requirements of regulatory inspections.

The regulatory landscape for industrial safety floor mats includes standards from organizations such as OSHA, NFPA, and industry-specific associations. These regulations often specify requirements for electrical safety, fire resistance, chemical compatibility, and performance testing procedures. Maintaining compliance requires ongoing attention to standard updates and verification that installed systems continue to meet current requirements throughout their service life.

Quality Assurance and Testing

Quality assurance programs for industrial safety floor mats involve comprehensive testing procedures that verify performance characteristics and durability under simulated operating conditions. Testing protocols typically include pressure sensitivity verification, signal transmission reliability, and resistance to environmental factors such as temperature extremes and chemical exposure. These testing programs provide objective data supporting mat selection decisions and warranty coverage.

The certification process for industrial safety floor mats involves independent verification of compliance with applicable standards and performance specifications. Third-party testing laboratories conduct standardized evaluations that provide unbiased assessment of mat capabilities and limitations. This certification process ensures that safety-critical applications receive products that meet established performance criteria and provide reliable protection for workers and equipment.

FAQ

How do pressure-sensitive industrial safety floor mats integrate with existing machinery safety systems

Pressure-sensitive industrial safety floor mats integrate with existing machinery through standardized electrical interfaces that connect to safety relay circuits, programmable logic controllers, or emergency stop systems. The mats output normally closed or normally open signals that can be wired into safety circuits to trigger immediate machinery shutdowns when pressure is detected. Integration typically requires coordination with safety system engineers to ensure proper signal interpretation and response timing that meets safety requirements for specific equipment and processes.

What maintenance intervals are recommended for anti-static industrial safety floor mats

Anti-static industrial safety floor mats require regular conductivity testing at intervals determined by facility risk assessment and manufacturer recommendations, typically ranging from monthly to quarterly depending on environmental conditions and usage intensity. Visual inspections should occur weekly to identify wear patterns, contamination, or damage that might compromise anti-static properties. Surface cleaning with appropriate anti-static solutions should follow established schedules based on contamination levels, while comprehensive resistance testing provides objective verification of continued anti-static effectiveness.

Can industrial safety floor mats be customized for specific facility layouts and requirements

Most industrial safety floor mats offer extensive customization options including dimensional specifications, sensor zone configurations, signal output types, and material selections tailored to specific applications. Manufacturers typically provide engineering support to develop custom solutions that address unique facility layouts, environmental conditions, and integration requirements. Customization options may include specialized shapes, multiple signal zones, enhanced chemical resistance, and integration with facility-specific control systems while maintaining compliance with applicable safety standards.

What factors should be considered when selecting industrial safety floor mats for chemical processing environments

Chemical processing environments require industrial safety floor mats with verified chemical resistance to specific compounds present in the facility, along with appropriate drainage systems for spill management and easy decontamination procedures. Material selection must consider temperature ranges, UV exposure, and potential for chemical reaction or degradation over time. Additional considerations include anti-static properties for flammable environments, pressure sensitivity calibration that accounts for chemical protective equipment worn by workers, and compliance with industry-specific safety standards for chemical processing operations.

Table of Contents

- Pressure-Sensitive Safety Mat Systems

- Anti-Static Floor Protection Solutions

- Heavy-Duty Industrial Mat Applications

- Installation and Maintenance Considerations

- Compliance and Standards

-

FAQ

- How do pressure-sensitive industrial safety floor mats integrate with existing machinery safety systems

- What maintenance intervals are recommended for anti-static industrial safety floor mats

- Can industrial safety floor mats be customized for specific facility layouts and requirements

- What factors should be considered when selecting industrial safety floor mats for chemical processing environments