Durability and Environmental Resistance

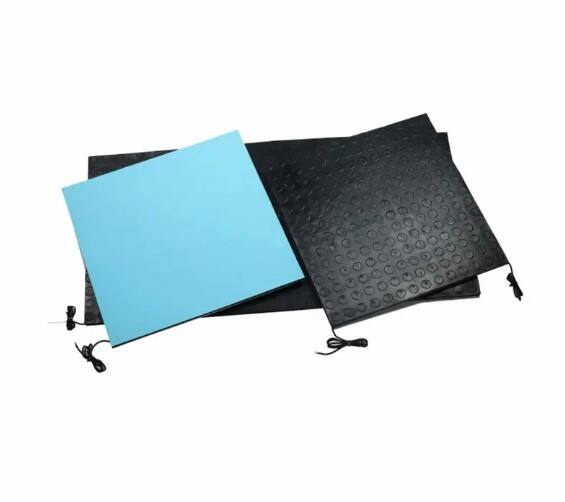

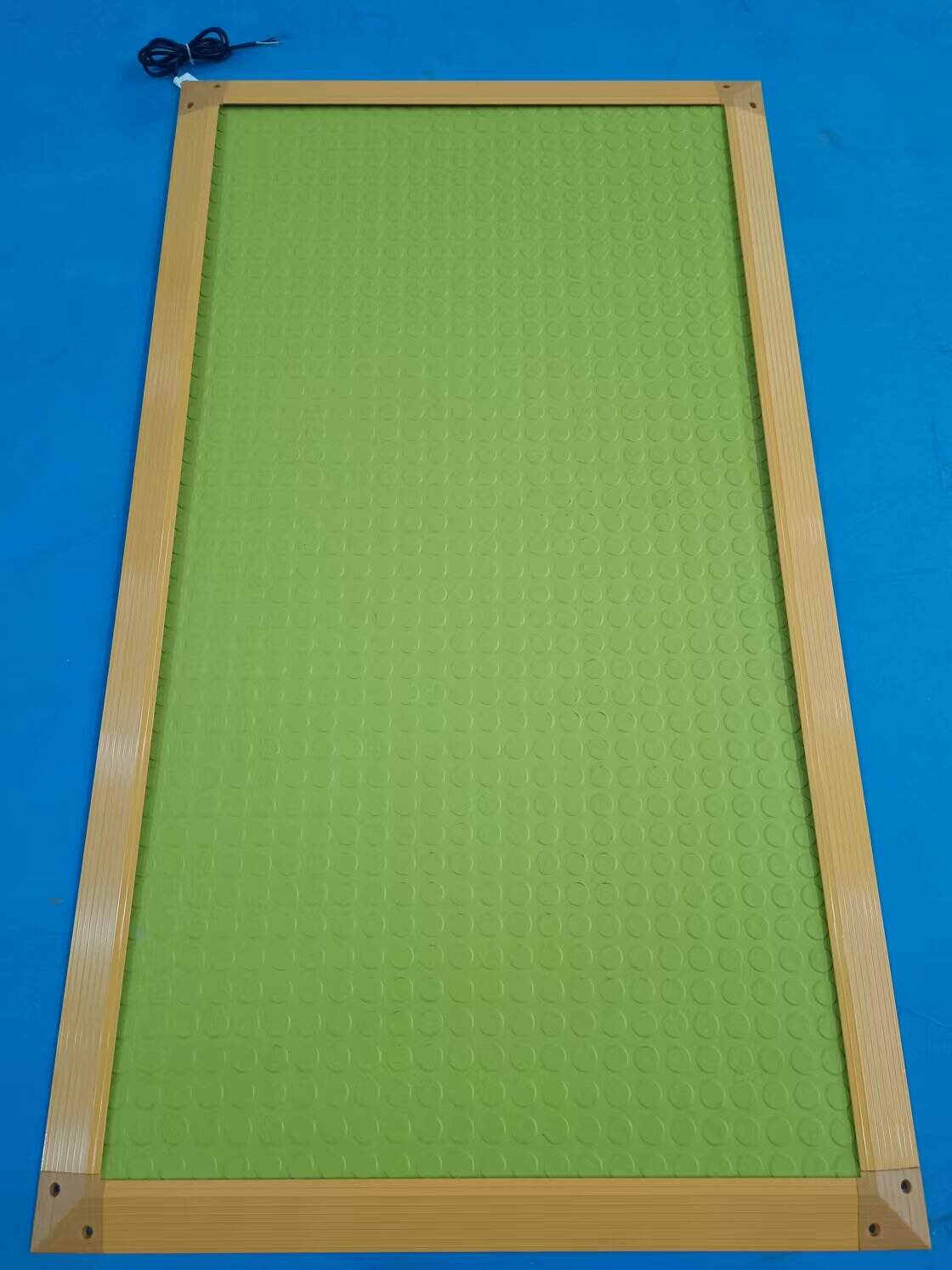

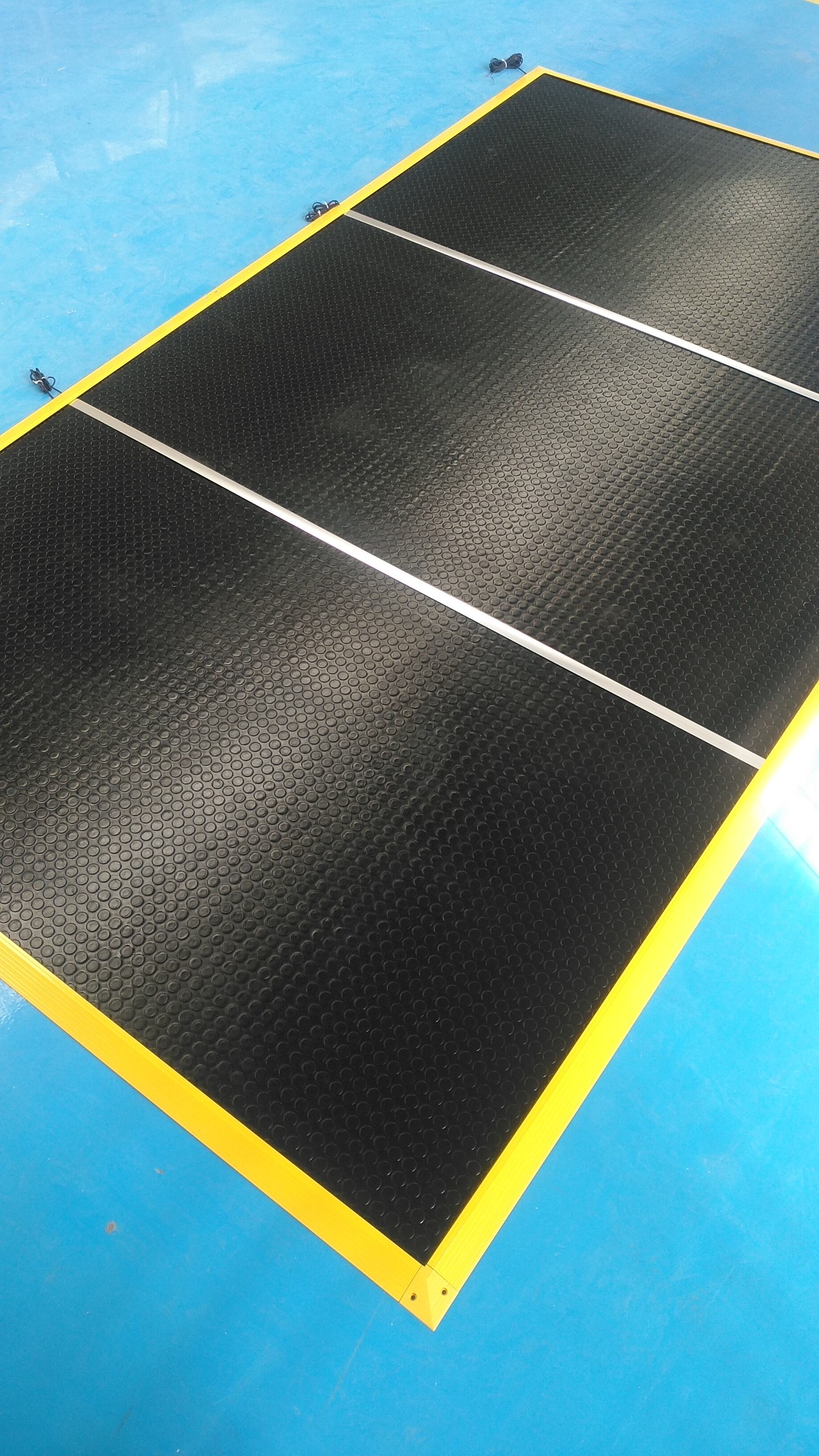

Safety switch mats are engineered for exceptional durability in demanding industrial environments. The construction utilizes high-grade materials that resist degradation from common industrial substances, including oils, coolants, and cleaning agents. The outer layer typically features reinforced vinyl or polyurethane compounds that withstand heavy foot traffic, equipment movement, and impact from dropped tools or materials. Internal components are sealed against moisture and dust ingress, maintaining reliable operation even in challenging conditions. The mats undergo rigorous testing for temperature extremes, chemical exposure, and mechanical stress, ensuring consistent performance throughout their operational lifetime. This robust construction translates to reduced maintenance requirements and lower total cost of ownership, while the sealed design prevents internal contamination that could compromise safety functionality.