Why Safety Carpets Are Essential in Factories

Slip resistant carpets play a big role in stopping those common workplace mishaps we all know too well – slips, trips, and falls. The National Safety Council actually reports that these kinds of accidents make up around 25% of all workplace incident reports. These special mats help cut down on the danger by giving workers something solid underfoot in spots where floors tend to get slippery from spills or just plain old wear and tear. Take factory entrances for example, where rainwater tends to puddle after storms, or food processing areas where liquid leaks happen regularly. The right kind of safety carpet will soak up excess moisture and give employees better traction when their shoes might otherwise slide right out from under them.

Safety carpets help reduce risks while making workers safer and actually improving how much gets done around the factory floor. Workers who don't worry about slipping or falling tend to concentrate better on what needs doing, which means fewer incidents and less time lost when something goes wrong. The peace of mind these carpets provide builds trust among staff members, creating an atmosphere where safety matters just as much as production numbers. Factories save money too because there are fewer injury-related claims against them and machines stay running longer without interruptions. For manufacturers looking to keep operations smooth and costs under control, investing in good quality safety flooring makes complete business sense beyond just meeting OSHA requirements.

Key Features of Effective Safety Carpets

Durability and Longevity

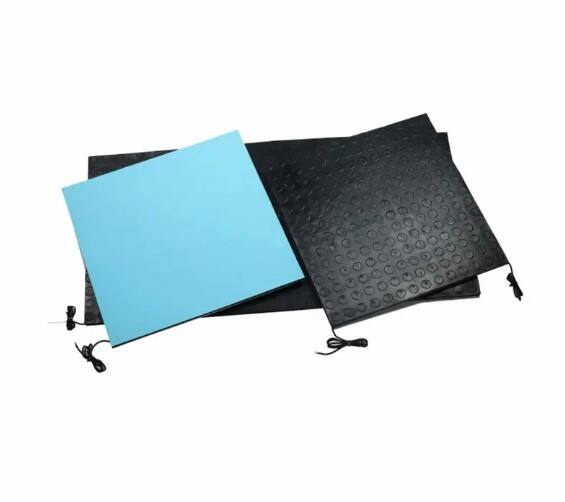

Safety carpets made from tough materials such as rubber or vinyl can handle all the constant walking around that happens in factories every day. Because they don't break down so easily, companies don't need to replace them as often, saving money over time. Factories that choose good quality safety flooring usually find that their investment lasts much longer than cheaper alternatives. These carpets resist damage from machinery, spills, and daily wear, often staying in service for three to five years even under tough conditions. Some manufacturers report cutting replacement costs by nearly half after switching to more durable options.

Slip-Resistant Properties

Safety carpets have those slip-resistant properties that really matter when it comes to keeping workers safe from accidents on the job. These carpets come with special textured surfaces designed to give people a good grip underfoot, which cuts down on slips happening, particularly where floors might get wet or greasy from machinery leaks. When manufacturers test how slippery these carpets actually are, they check against various safety standards so employers know they meet regulatory requirements. This kind of third party verification gives business owners peace of mind knowing their investment works as promised for workplace safety purposes.

Easy Maintenance and Cleaning

How easy something stays clean matters a lot when talking about good safety carpets, especially in those hectic factory floors where people are constantly moving around. Most modern safety carpets just don't get stained easily and wipe down pretty quickly with whatever cleaning stuff happens to be handy. Think about oil spills from machinery or food particles in processing plants these days. Factories love this kind of carpet because it keeps things looking decent without needing someone to spend hours scrubbing every day. Just a quick mop here and there does the trick most of the time.

The Role of Safety Carpets in Compliance

Meeting OSHA Standards

Safety carpets are essential tools for businesses trying to stay within OSHA's safety rules, those federal regulations that require employers to maintain workplaces free from recognized hazards. What many don't realize is that these aren't just suggestions they have actual teeth behind them, carrying real penalties for violations. Companies installing anti-slip safety carpets specifically engineered to grip surfaces and cut down on slips and falls find themselves ticking off several OSHA boxes at once. Beyond protecting staff members from injuries, proper carpeting helps avoid costly citations and potential lawsuits when accidents do happen. For facility managers, keeping up with OSHA compliance isn't just about avoiding trouble it's about creating environments where employees feel secure doing their jobs day after day without worrying about tripping over wet floors or slick spots.

Reducing Workplace Liability

Putting down safety carpets around the workplace really cuts down on legal troubles from employee injuries. These mats act as a buffer against those nasty slips, trips, and falls that happen all too often in offices and factories. The numbers back this up too - Liberty Mutual did some research showing these kinds of accidents drain companies of billions every year through worker compensation payouts and lost productivity time. When businesses actually focus on installing good quality safety carpets throughout their facilities, they tend to see lower insurance premiums and fewer court cases popping up over slip-and-fall claims. Investing in proper floor coverings isn't just about compliance either; smart employers know that creating a safer space for staff means everyone gets to work without worrying about walking into trouble.

Benefits of Safety Carpets Beyond Safety

Improving Workplace Aesthetics

Safety carpets do more than just serve their practical purpose. They actually make a big difference when it comes to how good a workspace looks. With so many different patterns and color choices on the market today, businesses can really spruce up what might otherwise be pretty boring office floors. When workers walk into an area that looks nice instead of sterile, it tends to lift their spirits quite a bit. Plus, companies that invest in better looking environments often see fewer people leaving for other jobs. Employees generally appreciate working somewhere where management clearly cares about creating a pleasant atmosphere rather than just ticking boxes on safety requirements.

Reducing Fatigue and Strain

Safety carpets with their cushioning features really cut down on employee fatigue and strain throughout the day. Workers who stand for hours on end find these floors much more comfortable than hard surfaces. Studies have shown time and again that when companies invest in good quality flooring, it makes a big difference in how workers feel physically at the end of their shifts. Less tired workers mean better productivity numbers across the board. Plus, businesses see fewer sick days and lower healthcare costs because employees aren't hurting as much after work. For manufacturing plants and warehouses especially, switching to these safety carpets pays off in both worker satisfaction and bottom line results.

Choosing the Right Safety Carpets for Your Factory

Assessing Factory Needs

Picking out the best safety carpets starts by looking closely at what's actually happening on the factory floor. Traffic volume matters a lot, along with the kind of equipment running around and whether there are spills or chemical exposure risks. A good site survey really makes a difference here because it tells us if standard options will work or if we need something special for those tricky areas. When companies take this step seriously, they usually find that certain features become obvious requirements like non-slip surfaces or extra tough materials that can handle heavy foot traffic day after day without wearing down too quickly.

Comparing Materials and Designs

Safety carpets come in different materials, and picking the best option means looking at what works for particular situations. Rubber tends to hold up well in areas where spills happen often, while vinyl might be better suited for places needing easy cleaning. Carpet tiles can sometimes make sense too, especially when factories want modular solutions. When evaluating options, companies should think about how much money they have to spend, how much work goes into keeping things clean, and what kind of effect these choices will have on the planet. The goal is finding something that keeps workers safe without breaking the bank or causing unnecessary harm to the environment. Most manufacturers find themselves walking this fine line between protection, cost control, and sustainability concerns every time they upgrade flooring systems.

FAQ Section

What are safety carpets?

Safety carpets are specially designed carpets used in industrial settings to provide a slip-resistant surface, reduce accidents, and enhance worker safety in areas prone to spills or uneven surfaces.

Why are safety carpets important in factories?

Safety carpets are crucial in factories as they prevent slips, trips, and falls, which are common workplace incidents. They also enhance productivity by creating a secure work environment and reducing the risk of injuries, compensation claims, and downtime.

How do safety carpets help in compliance with OSHA standards?

Safety carpets help companies adhere to OSHA standards by providing a safe working environment that decreases the likelihood of slip-related incidents, thereby meeting legal safety requirements and avoiding fines and legal issues.

What materials are used in safety carpets?

Safety carpets are commonly made from durable materials like rubber, vinyl, and specialized textiles that offer slip-resistant properties, durability, and ease of maintenance.

Can safety carpets enhance the aesthetics of a workplace?

Yes, safety carpets come in various designs and colors, allowing them to improve workplace aesthetics, boost employee morale, and contribute positively to the overall company image.