safety mats for machines

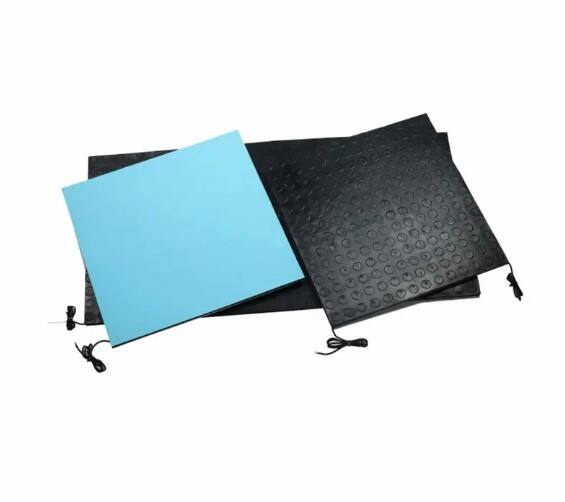

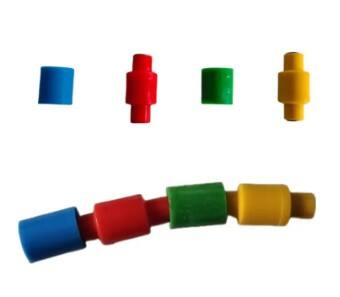

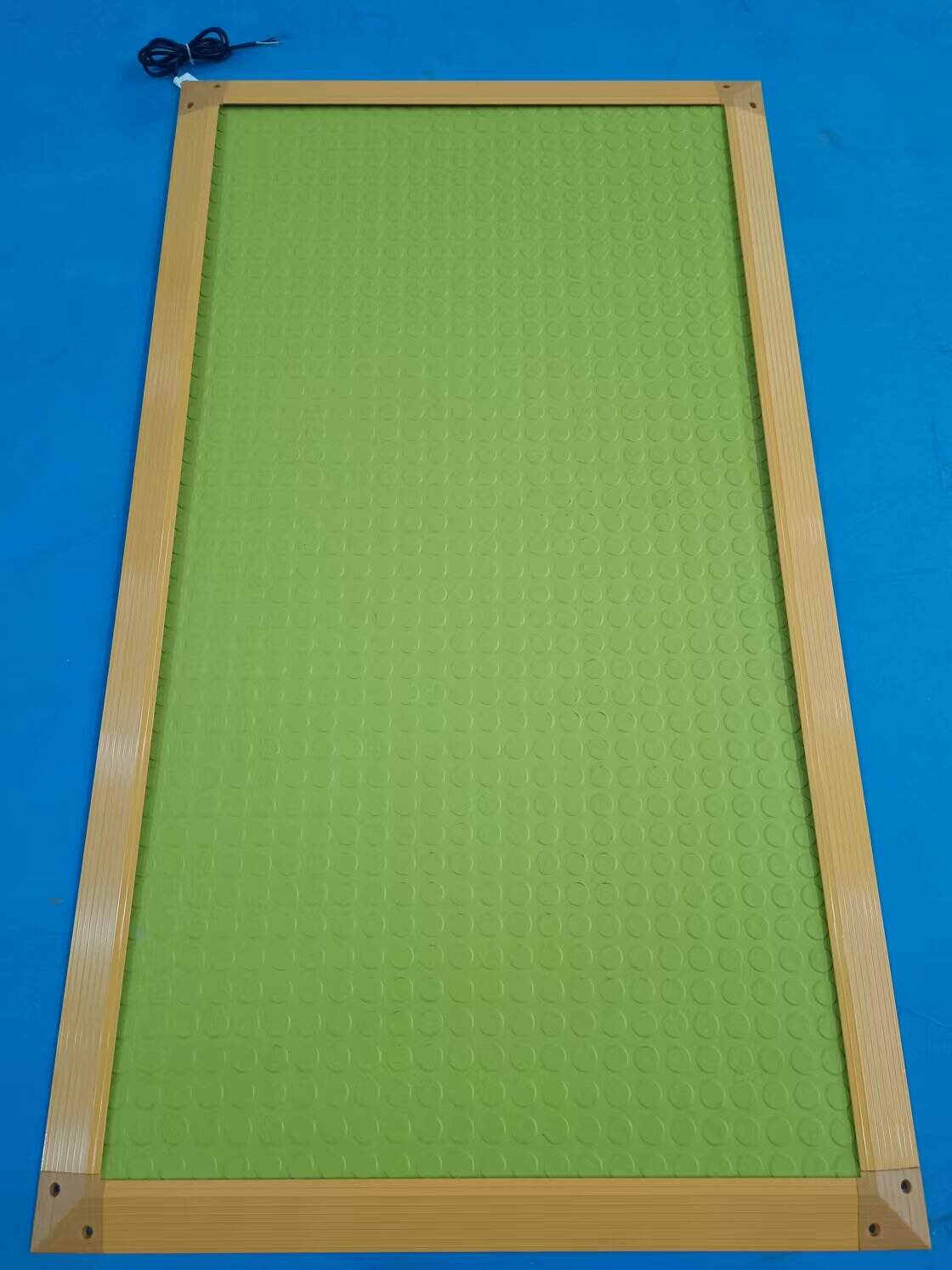

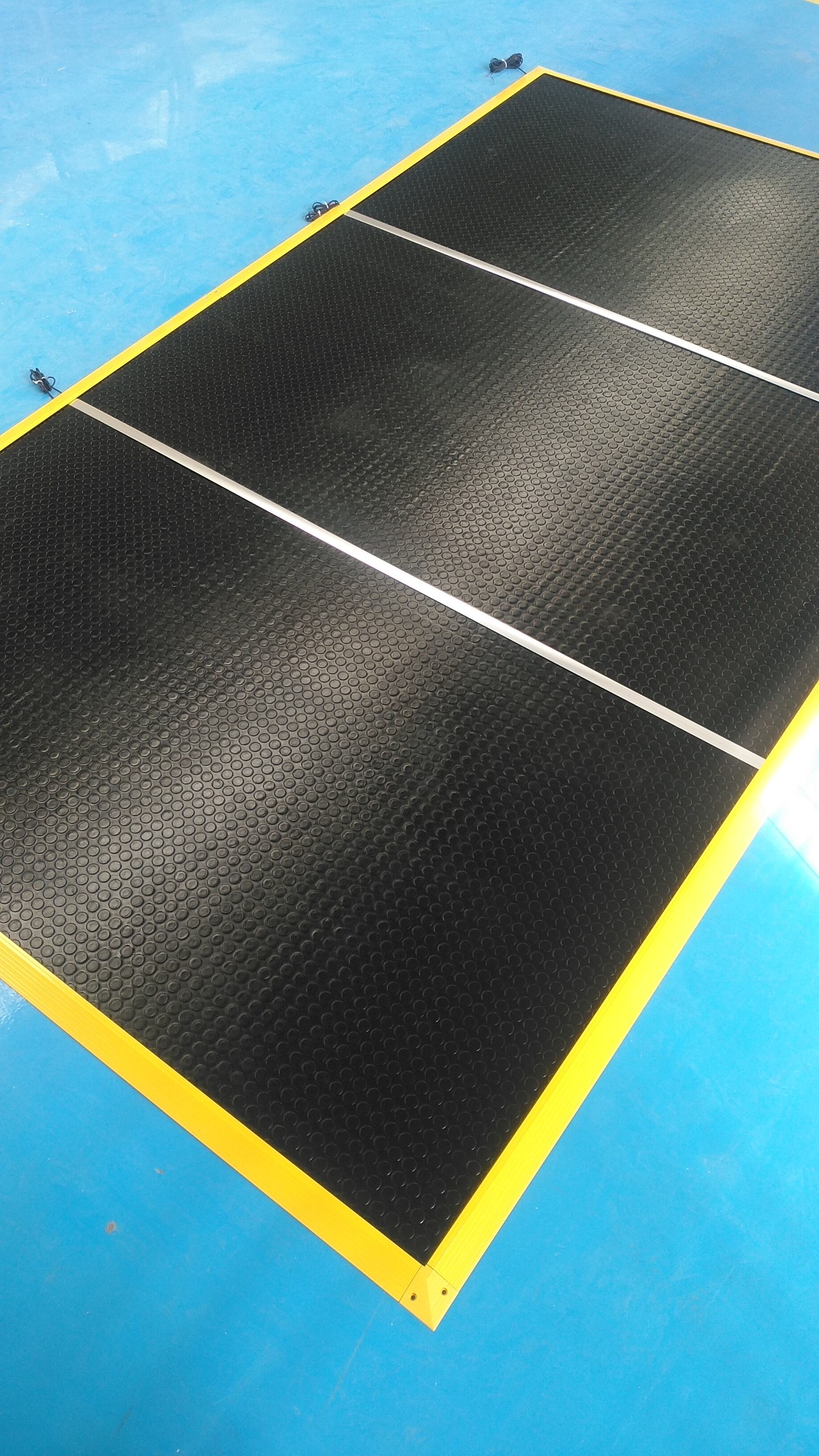

Safety mats for machines represent a critical component in industrial safety systems, serving as pressure-sensitive protective devices that detect personnel presence in hazardous areas. These robust mats are engineered with multiple layers of durable materials, incorporating sophisticated sensor technology that instantly responds to applied pressure. When activated, they trigger immediate machine shutdowns or safety protocols, effectively preventing accidents and injuries. The mats feature fail-safe design principles, ensuring they remain functional even under challenging industrial conditions. Typically installed around dangerous machinery, robotic systems, and automated manufacturing equipment, these mats create invisible safety zones that protect workers from potential hazards. Their construction includes a non-slip surface texture for stable footing, while internal components are sealed against dust and moisture penetration, meeting IP67 standards. The mats can be interconnected to cover larger areas and integrate seamlessly with existing safety systems through standard safety controllers. They comply with international safety standards including ISO 13856-1 and EN ISO 13849-1, making them suitable for global deployment. Modern safety mats incorporate self-monitoring capabilities, continuously checking for system integrity and alerting maintenance personnel to any operational issues.