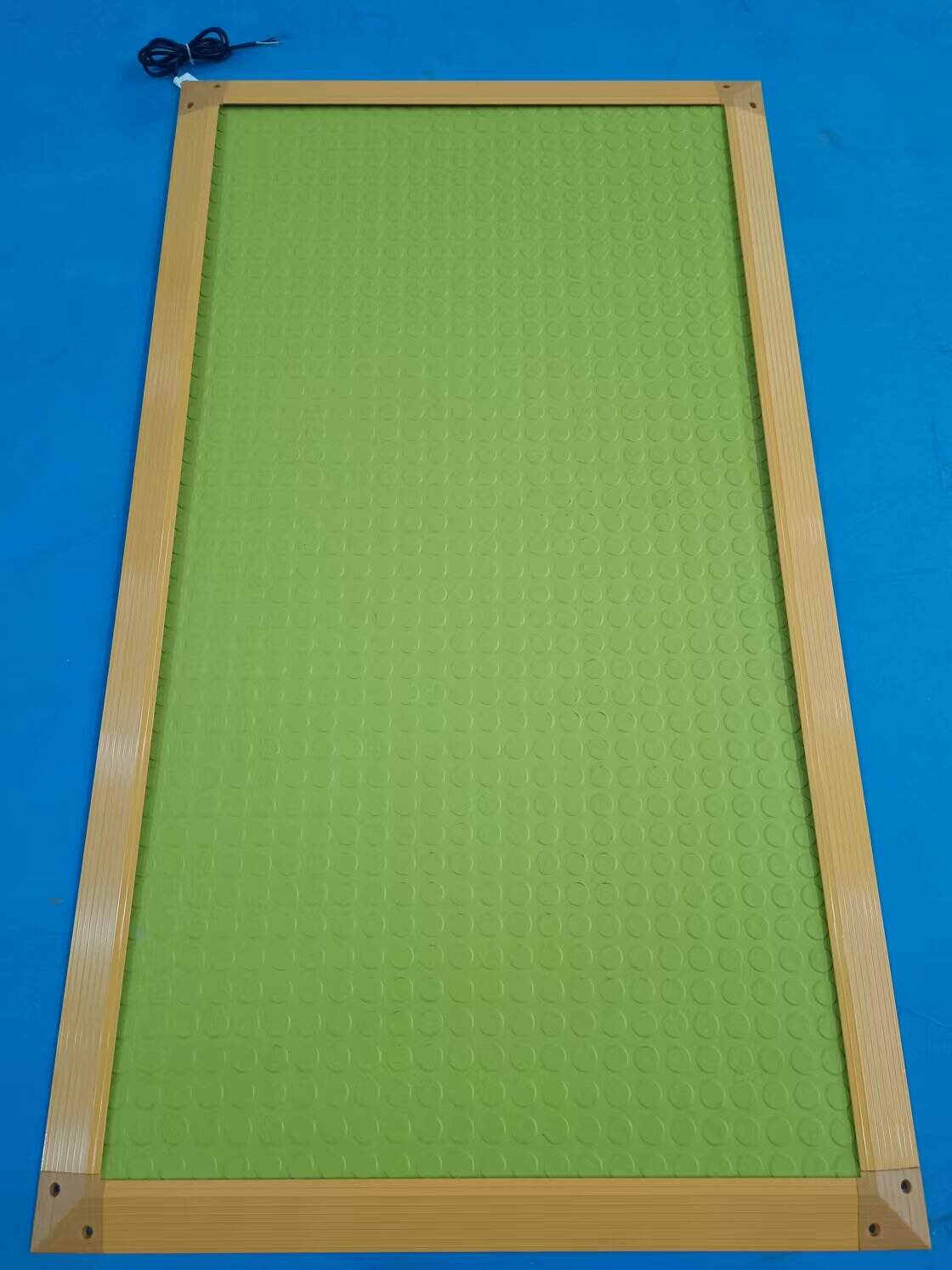

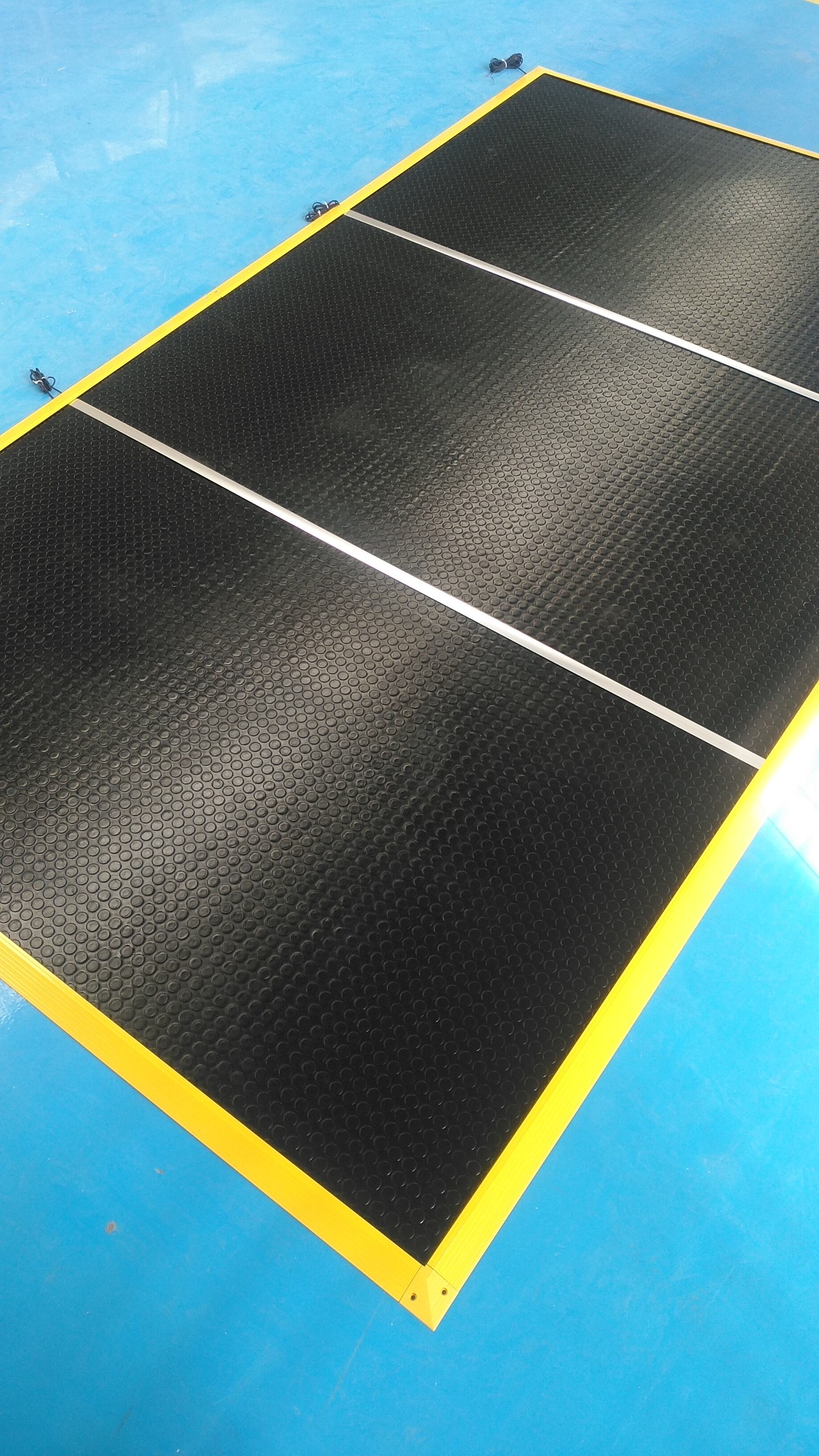

rubber mats for electrical safety

Rubber mats for electrical safety represent a crucial line of defense in protecting workers from electrical hazards in various industrial and commercial settings. These specialized mats are engineered with high-quality insulating rubber compounds that provide excellent resistance against electrical current flow. The mats are designed to withstand specific voltage levels, typically ranging from 1,000V to 30,000V, making them suitable for different electrical environments. These safety mats feature a non-slip surface pattern that ensures stable footing, while their durable construction resists oils, acids, and other common industrial chemicals. The manufacturing process involves rigorous testing procedures to ensure compliance with international safety standards, including ASTM D178 and IEC 61111. Modern electrical safety mats incorporate advanced features such as color-coded layers that serve as wear indicators, ensuring timely replacement when necessary. Their applications span across power generation facilities, electrical substations, switchgear rooms, transformer areas, and maintenance workshops. The mats' thickness typically ranges from 1/8 inch to 1/2 inch, depending on the voltage rating and specific application requirements. These essential safety tools also feature beveled edges to prevent tripping hazards and are available in various sizes to accommodate different workspace configurations.