safety relay switch

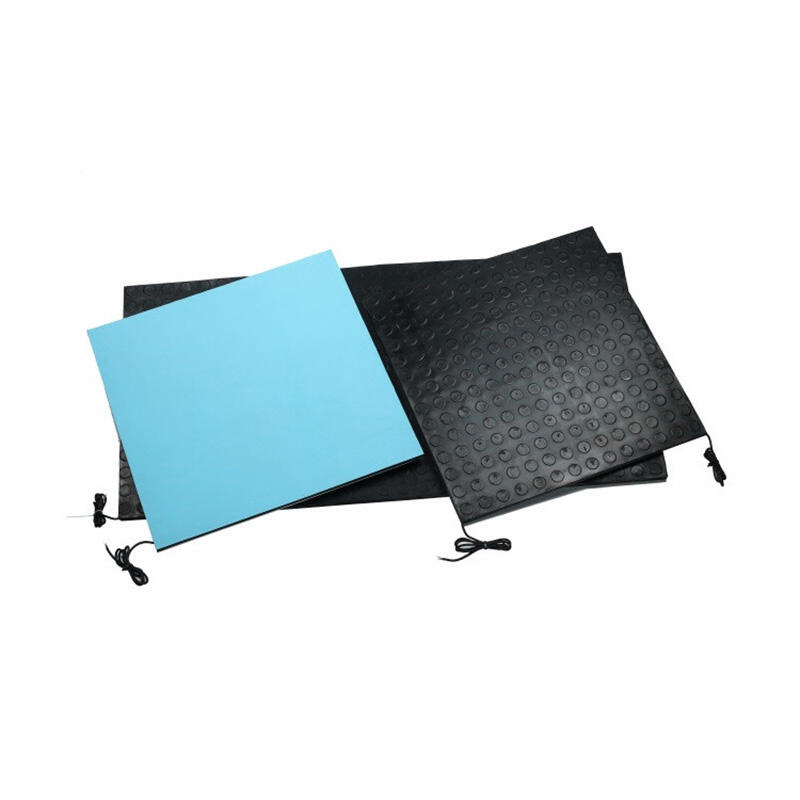

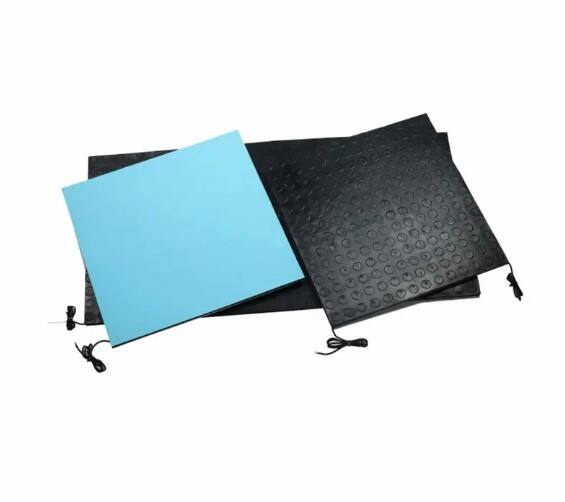

A safety relay switch is a critical component in industrial safety systems, designed to monitor and control emergency stop functions and safety devices. This sophisticated device serves as a reliable safeguard, ensuring immediate machine shutdown when dangerous conditions are detected. Operating through redundant circuits and self-monitoring capabilities, safety relay switches provide fail-safe operation by continuously checking their own functionality. These devices integrate seamlessly with various safety components such as emergency stop buttons, light curtains, safety gates, and pressure-sensitive mats. The switch employs dual-channel architecture with diversity, meaning it uses different types of contacts and monitoring methods to prevent common mode failures. Modern safety relay switches feature LED indicators for quick status assessment, replaceable terminals for easy maintenance, and compatibility with both mechanical and electronic safety sensors. They comply with international safety standards including ISO 13849-1 and IEC 61508, making them suitable for applications up to Safety Integrity Level (SIL) 3 and Performance Level (PL) e. Their versatility allows implementation across numerous industries, from manufacturing and packaging to robotics and material handling systems.