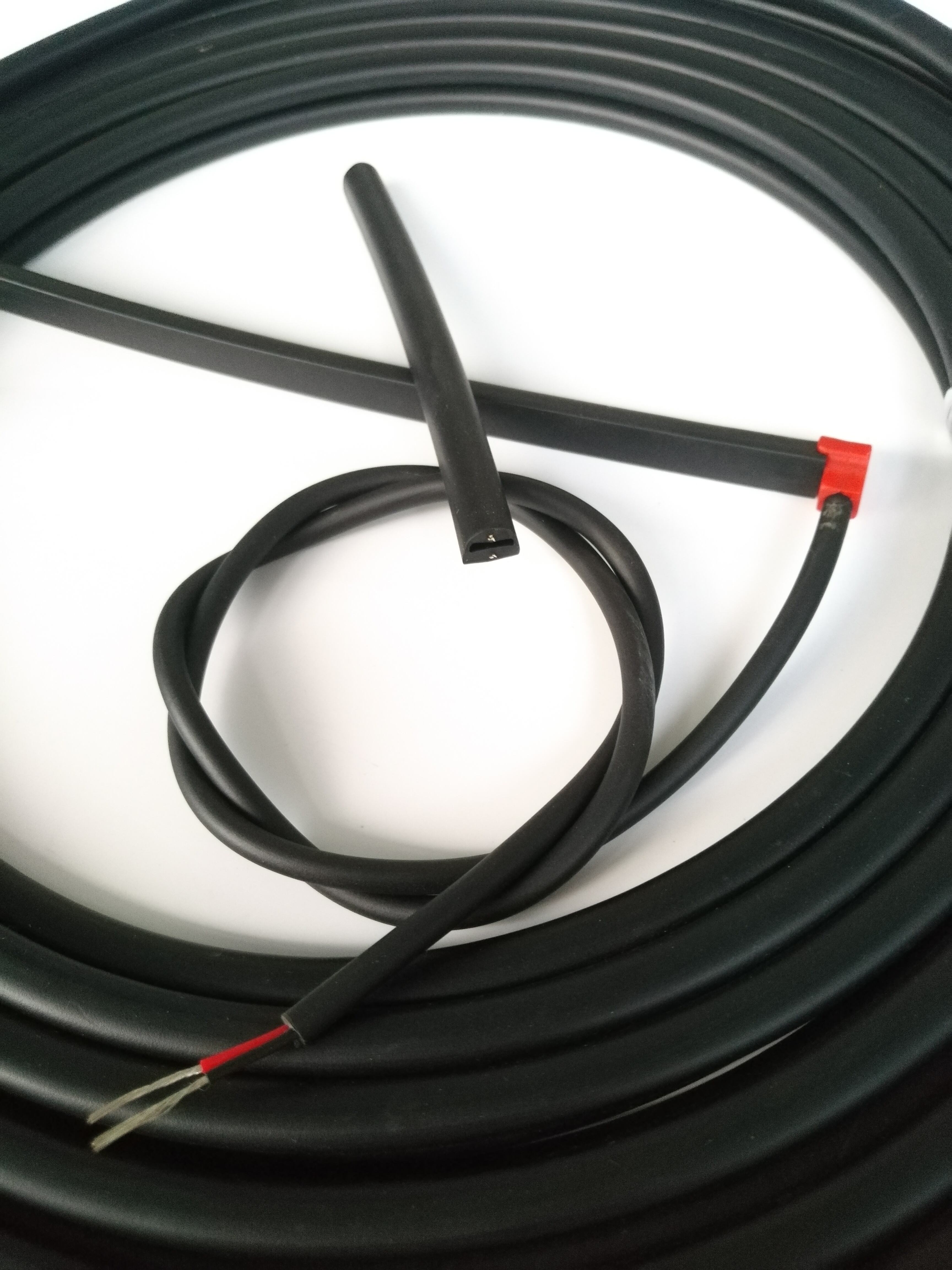

conductive rubber strip

A conductive rubber strip is an innovative electrical component that combines the flexibility of rubber with electrical conductivity. This versatile material consists of a specialized rubber compound infused with conductive particles, typically carbon black or metal powders, creating a unique combination of mechanical and electrical properties. The strip serves as an effective interface between electronic components and provides reliable electrical connections while maintaining the elastic properties of rubber. With thickness variations ranging from 0.5mm to 5mm and customizable widths, these strips can be manufactured to meet specific requirements. The material's structure allows for excellent compression recovery and consistent electrical conductivity across its surface, making it ideal for various applications. In electronics manufacturing, conductive rubber strips are extensively used in keypads, membrane switches, and EMI/RFI shielding. They excel in environments where traditional metal conductors might fail due to vibration or movement. The strips maintain their conductivity even under repeated compression and extension cycles, ensuring long-term reliability. Their weather-resistant properties and ability to operate across a wide temperature range make them suitable for both indoor and outdoor applications. Additionally, these strips offer excellent resistance to environmental factors such as moisture, dust, and chemical exposure, contributing to their durability and extended service life.