Industrial workplaces face constant challenges when it comes to maintaining employee safety and preventing accidents. Among the most effective solutions available today are safety carpets, which serve as critical protective barriers in high-risk environments. These specialized floor coverings provide immediate hazard detection and emergency response capabilities, making them indispensable for modern manufacturing facilities, automated production lines, and heavy machinery operations. The implementation of safety carpets has revolutionized workplace safety protocols by offering real-time monitoring and instant shutdown capabilities when potential dangers are detected.

Understanding the Technology Behind Safety Carpets

Pressure-Sensitive Detection Mechanisms

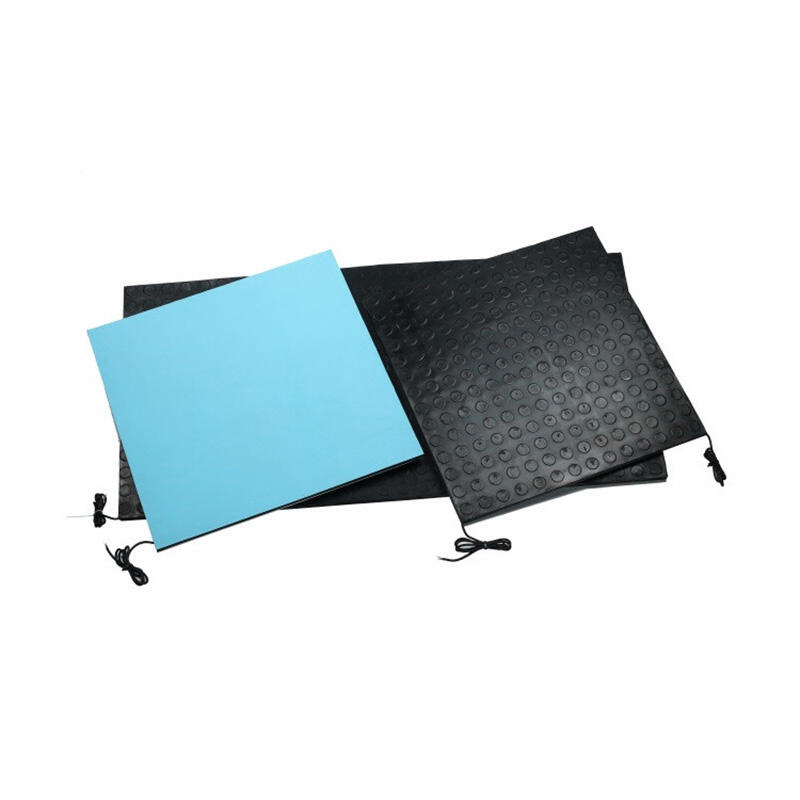

Safety carpets utilize advanced pressure-sensitive technology that responds instantly to human presence or unauthorized access. These systems incorporate multiple layers of conductive materials that create electrical circuits, which are broken when pressure is applied to the surface. The sensitivity levels can be calibrated to detect various weight thresholds, ensuring that both personnel and equipment are properly monitored. This technology provides reliable detection capabilities even in harsh industrial environments where dust, moisture, and temperature fluctuations are common.

The detection mechanism operates through a series of embedded sensors that create a comprehensive safety net across designated areas. When an individual steps onto the carpet surface, the pressure triggers an immediate signal transmission to connected safety systems. This instantaneous response capability makes safety carpets particularly valuable in applications where even milliseconds can determine the difference between safety and serious injury. The technology has been refined over decades to eliminate false positives while maintaining maximum sensitivity to legitimate safety concerns.

Signal Transmission and Integration Capabilities

Modern safety carpets feature sophisticated signal transmission systems that integrate seamlessly with existing industrial control networks. These systems support multiple communication protocols, including hardwired connections, wireless transmission, and industrial ethernet compatibility. The signal output can be configured to trigger emergency stops, activate warning alarms, or initiate automated safety sequences depending on the specific application requirements. This flexibility allows safety carpets to serve as central components in comprehensive safety management systems.

Integration capabilities extend beyond basic on-off switching to include diagnostic monitoring and maintenance alerts. Advanced safety carpet systems provide continuous feedback about their operational status, detecting potential issues before they compromise safety functionality. This proactive approach to system monitoring ensures that safety carpets maintain peak performance throughout their operational lifespan, reducing the risk of unexpected failures during critical safety situations.

Industrial Applications and Implementation Benefits

Manufacturing and Production Line Safety

In manufacturing environments, safety carpets serve as essential protective barriers around dangerous machinery and automated equipment. They create invisible safety zones that immediately halt operations when personnel enter restricted areas, preventing accidents caused by moving parts, robotic systems, or hazardous processes. The implementation of safety carpets in production facilities has significantly reduced workplace injuries while maintaining operational efficiency through quick reset capabilities.

Production line applications benefit from the non-intrusive nature of safety carpets, which allow normal workflow to continue unimpeded while providing constant protection. Unlike physical barriers or light curtains that can interfere with material handling and equipment access, safety carpets create protective zones at floor level without obstructing visibility or movement paths. This design advantage makes them particularly suitable for applications involving overhead cranes, conveyor systems, and automated guided vehicles where traditional safety devices might create operational complications.

Warehouse and Logistics Operations

Warehouse environments present unique safety challenges due to the constant movement of personnel, forklifts, and automated storage systems. Safety carpets provide effective protection in loading dock areas, where the risk of falls and equipment collisions is particularly high. They can be strategically positioned to detect when personnel approach dangerous zones such as dock edges, machinery maintenance areas, or automated sorting systems. The immediate response capability of safety carpets helps prevent accidents that could result in serious injuries or costly equipment damage.

Logistics operations benefit from the durability and reliability of industrial-grade safety carpets designed to withstand heavy foot traffic and equipment loads. These systems maintain their sensitivity and responsiveness even under demanding conditions, including exposure to chemicals, temperature variations, and mechanical stress. The long-term reliability of safety carpets makes them cost-effective investments that provide continuous protection while minimizing maintenance requirements and operational disruptions.

Technical Advantages and Performance Characteristics

Durability and Environmental Resistance

Industrial safety carpets are engineered to withstand extreme environmental conditions commonly found in manufacturing and processing facilities. They feature robust construction materials that resist chemical exposure, temperature fluctuations, and mechanical wear from heavy equipment traffic. The sealed design prevents moisture infiltration and contamination, ensuring consistent performance in wet or dusty environments where other safety devices might fail or require frequent maintenance.

The longevity of safety carpets represents a significant advantage over alternative safety solutions that may require regular replacement or recalibration. Quality safety carpet systems can operate reliably for years without degradation in sensitivity or response time, providing consistent protection throughout their service life. This durability translates into lower total cost of ownership and reduced maintenance overhead compared to more complex safety systems requiring frequent servicing or component replacement.

Installation Flexibility and Customization Options

Safety carpets offer exceptional installation flexibility, allowing them to be configured for virtually any floor layout or application requirement. They can be cut to custom dimensions, joined to create larger coverage areas, or shaped to fit around existing equipment and infrastructure. This adaptability makes safety carpets suitable for both new facility construction and retrofit applications where existing layouts must be accommodated without major modifications.

Customization options extend to sensitivity settings, response timing, and output signal characteristics to match specific application needs. Different areas within a facility may require different safety parameters, and safety carpets can be individually configured to provide appropriate protection levels for each zone. This flexibility allows facility managers to implement comprehensive safety strategies that address the unique risks present in different operational areas while maintaining consistent protection standards throughout the facility.

Economic Benefits and Return on Investment

Accident Prevention and Cost Reduction

The implementation of safety carpets provides substantial economic benefits through accident prevention and associated cost reductions. Workplace injuries result in direct costs including medical expenses, workers compensation claims, and lost productivity, as well as indirect costs such as investigation time, replacement worker training, and potential regulatory penalties. Safety carpets help eliminate these costs by preventing accidents before they occur, creating measurable financial returns that often justify the initial investment within months of installation.

Insurance premium reductions represent another significant economic advantage of implementing comprehensive safety carpet systems. Many insurance providers offer reduced rates for facilities that demonstrate proactive safety management through the installation of certified safety equipment. The documented effectiveness of safety carpets in preventing workplace accidents makes them attractive risk mitigation tools that can lead to substantial insurance cost savings over time, further improving the overall return on investment.

Operational Efficiency and Productivity Gains

Safety carpets contribute to operational efficiency by enabling automated safety responses that minimize production disruptions. Traditional safety measures often require manual intervention or complex reset procedures that can halt operations for extended periods. Safety carpets provide instant protection with simple reset capabilities, allowing normal operations to resume quickly after safety events are resolved. This rapid recovery capability helps maintain production schedules and reduces the operational impact of safety incidents.

The reliability and low maintenance requirements of safety carpets eliminate the productivity losses associated with safety system downtime and maintenance activities. Unlike mechanical safety devices that may require regular calibration or component replacement, safety carpets operate consistently with minimal intervention. This reliability ensures that safety protection remains available when needed while avoiding the production delays that can result from safety system failures or maintenance requirements.

Regulatory Compliance and Industry Standards

Safety Standard Compliance Requirements

Industrial safety carpets must meet stringent regulatory requirements established by occupational safety organizations and industry standards bodies. These standards define performance criteria for response time, sensitivity levels, durability testing, and environmental resistance that ensure safety carpets provide reliable protection in demanding applications. Compliance with recognized standards such as ISO 13849 and IEC 61496 provides assurance that safety carpet systems meet established safety integrity levels appropriate for their intended applications.

Regular certification and testing requirements ensure that safety carpet systems maintain their protective capabilities throughout their operational life. Manufacturers must demonstrate compliance through rigorous testing protocols that verify performance under various environmental conditions and usage scenarios. This ongoing compliance verification provides facility managers with confidence that their safety carpet installations continue to meet regulatory requirements and provide effective protection for personnel and equipment.

Documentation and Audit Trail Requirements

Modern safety carpet systems provide comprehensive documentation capabilities that support regulatory compliance and safety auditing requirements. These systems can log safety events, system status changes, and maintenance activities to create detailed audit trails that demonstrate ongoing compliance with safety regulations. The availability of historical data helps facility managers identify trends, optimize safety procedures, and provide evidence of due diligence in maintaining workplace safety standards.

Automated reporting capabilities simplify the compliance documentation process by generating regular status reports and maintenance schedules. This automation reduces the administrative burden associated with safety system management while ensuring that all required documentation is maintained and readily available for regulatory inspections or internal audits. The comprehensive record-keeping capabilities of advanced safety carpet systems support continuous improvement initiatives and help organizations maintain their commitment to workplace safety excellence.

Installation and Maintenance Considerations

Proper Installation Techniques and Best Practices

Successful safety carpet installation requires careful attention to surface preparation, cable routing, and system integration to ensure optimal performance and longevity. The installation surface must be level, clean, and free from sharp objects or debris that could damage the carpet materials or interfere with sensor operation. Proper cable management prevents damage from foot traffic or equipment movement while maintaining the integrity of signal transmission paths between the carpet and control systems.

Professional installation services ensure that safety carpets are properly configured and tested before being placed into service. Installation teams verify sensitivity settings, test response times, and confirm integration with existing safety systems to ensure complete functionality. Proper installation documentation provides reference information for future maintenance activities and helps facility personnel understand system operation and troubleshooting procedures.

Preventive Maintenance and System Monitoring

Regular preventive maintenance extends the service life of safety carpet systems and ensures continued reliable operation. Maintenance activities include visual inspections for physical damage, cleaning of surface areas to maintain sensitivity, and periodic testing of response functions to verify proper operation. Scheduled maintenance programs help identify potential issues before they affect system performance, reducing the risk of unexpected failures that could compromise workplace safety.

Advanced safety carpet systems include self-monitoring capabilities that continuously check system status and alert operators to potential problems. These diagnostic features can detect issues such as sensor degradation, cable damage, or environmental conditions that might affect performance. Early warning capabilities allow maintenance teams to address problems proactively, minimizing system downtime and ensuring that safety protection remains available when needed.

FAQ

What is the typical lifespan of industrial safety carpets?

Industrial safety carpets are designed for long-term operation and typically provide reliable service for 5 to 10 years under normal industrial conditions. The actual lifespan depends on factors such as foot traffic volume, environmental exposure, and maintenance practices. High-quality safety carpets with proper installation and regular maintenance can often exceed their expected lifespan while maintaining full functionality and safety compliance requirements.

How do safety carpets perform in harsh environmental conditions?

Modern safety carpets are engineered to withstand challenging industrial environments including exposure to chemicals, temperature extremes, moisture, and mechanical stress. They feature sealed construction that prevents contamination and maintains sensitivity even in dusty or wet conditions. The robust design ensures consistent performance across a wide range of environmental conditions commonly found in manufacturing, processing, and warehouse facilities.

Can safety carpets be integrated with existing safety systems?

Safety carpets offer excellent integration capabilities with existing industrial control and safety systems through multiple communication protocols and output options. They can be connected to programmable logic controllers, safety relays, and emergency stop circuits to provide coordinated safety responses. The flexibility of modern safety carpet systems allows them to serve as components in comprehensive safety architectures while maintaining compatibility with legacy equipment and control systems.

What are the key factors to consider when selecting safety carpets for industrial applications?

Key selection factors include environmental conditions, traffic patterns, integration requirements, and specific safety objectives for the application. Consider the chemical resistance needed, temperature range, expected foot traffic volume, and any special requirements such as anti-static properties or explosion-proof certification. Proper sizing, sensitivity settings, and output signal compatibility with existing systems are also critical factors that influence system effectiveness and overall safety performance.