Enhancing Workplace Protection Through Advanced Floor Safety Solutions

Industrial environments present numerous challenges when it comes to worker safety, and one often overlooked yet crucial element is floor safety. Safety mats have emerged as an integral component of modern industrial safety systems, offering reliable protection for workers and equipment in various manufacturing and processing facilities. These sophisticated safety devices do more than just provide a non-slip surface - they create an intelligent barrier between workers and hazardous areas, helping prevent accidents and enhance overall workplace security.

As industrial automation continues to advance, the role of safety mats becomes increasingly significant in maintaining a secure work environment. These pressure-sensitive devices act as a final line of defense, automatically triggering emergency stops or warning systems when unauthorized entry is detected in dangerous zones. Understanding their capabilities and proper implementation can dramatically improve workplace safety standards and operational efficiency.

Understanding Safety Mat Technology and Applications

Core Components and Functionality

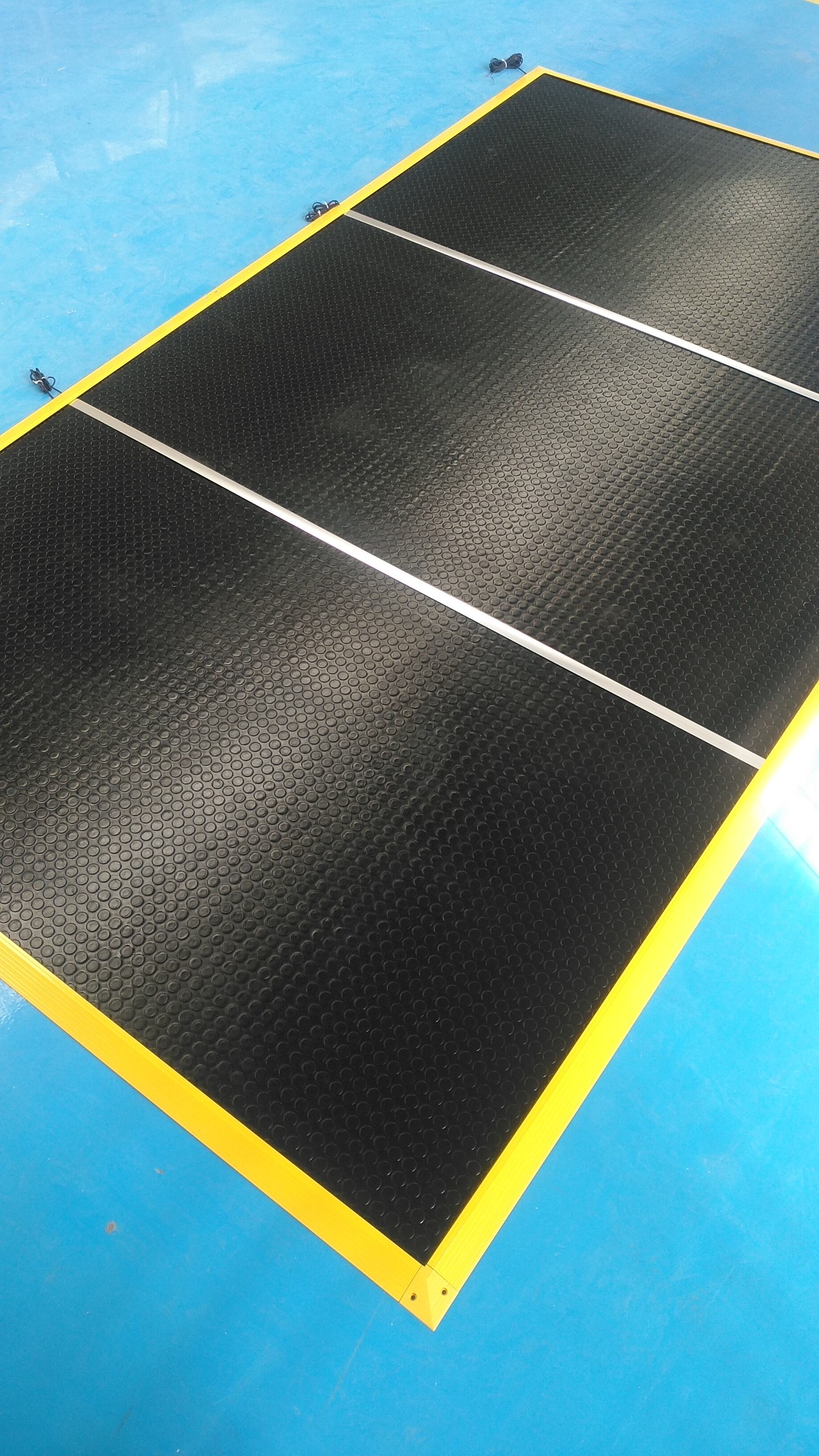

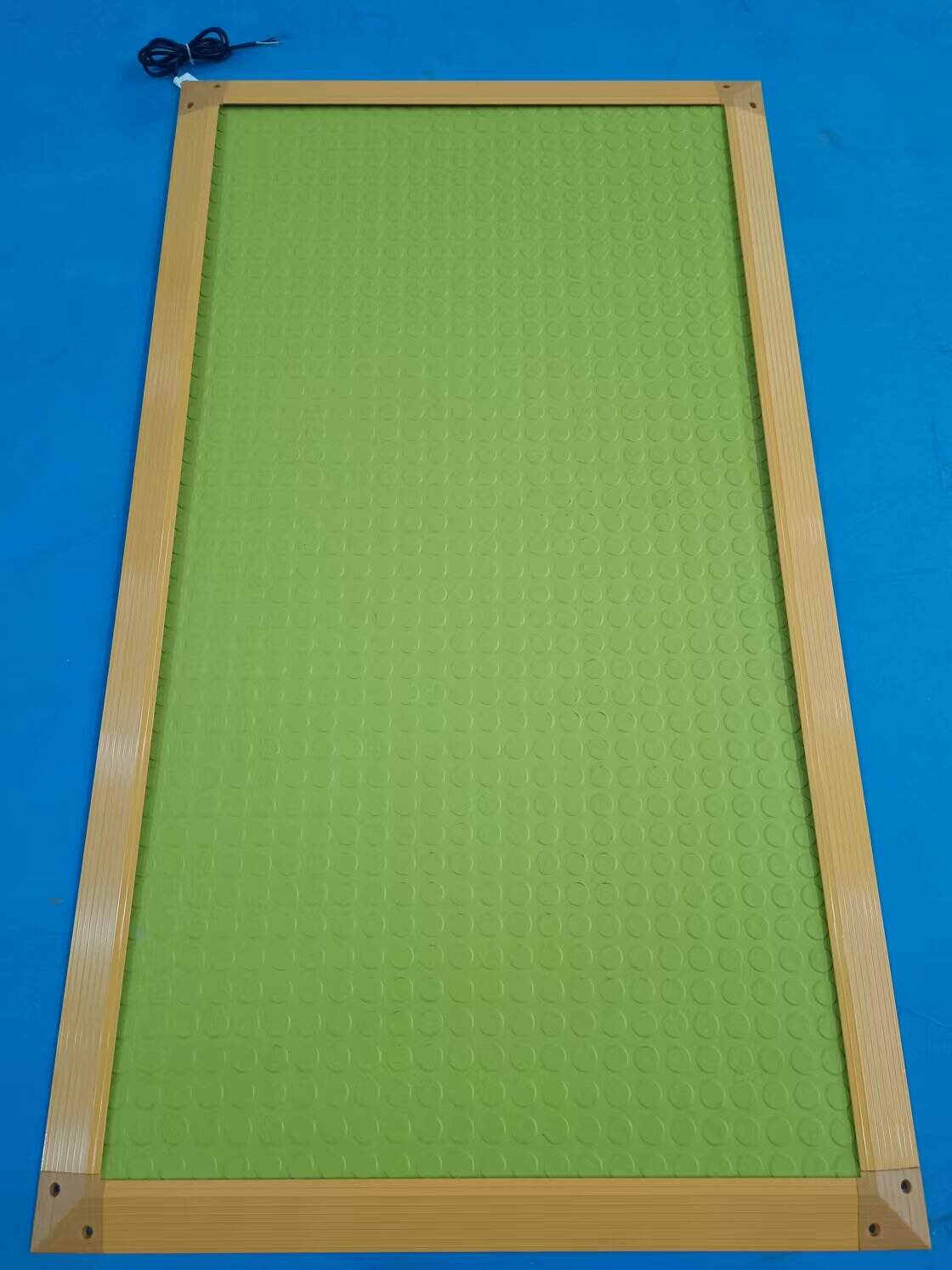

Safety mats incorporate sophisticated pressure-sensing technology within their durable construction. The interior consists of two electrically conductive plates separated by an insulating layer. When pressure is applied to the mat's surface, these plates make contact, triggering the connected safety system. This simple yet effective mechanism ensures reliable detection of human presence in hazardous areas.

The outer casing of safety mats is engineered to withstand harsh industrial conditions, featuring oil-resistant, anti-slip surfaces and sealed edges to prevent liquid infiltration. Modern safety mats also include fail-safe monitoring systems that continuously check for proper functionality, ensuring the safety system remains reliable throughout its operational life.

Strategic Placement and Integration

The effectiveness of safety mats largely depends on their strategic placement within the industrial setting. Common applications include positioning around robotic work cells, automated machinery, assembly lines, and other potentially dangerous equipment. When properly integrated with machine control systems, safety mats create an invisible barrier that immediately halts operations when breached.

Integration with existing safety systems requires careful consideration of factors such as response time, coverage area, and environmental conditions. Professional installation ensures optimal positioning and proper connection to emergency stop circuits, maximizing the protective capabilities of the safety mat system.

Benefits of Implementing Safety Mat Systems

Enhanced Worker Protection

The primary advantage of safety mats lies in their ability to provide immediate protection for workers entering hazardous areas. Unlike traditional barriers or warning signs, safety mats actively respond to human presence, triggering protective measures before an accident can occur. This proactive approach to safety has proven particularly valuable in environments with moving machinery or automated systems.

Workers gain confidence knowing that an additional layer of protection exists beneath their feet, allowing them to focus on their tasks without constant concern about accidental equipment activation. The psychological benefits of enhanced safety measures often translate into improved productivity and job satisfaction.

Regulatory Compliance and Risk Reduction

Implementation of safety mats helps facilities meet or exceed regulatory requirements for machine guarding and worker protection. These systems align with OSHA standards and international safety regulations, demonstrating a commitment to workplace safety and potentially reducing insurance premiums through improved risk management.

By documenting the installation and maintenance of safety mat systems, companies create a clear record of their safety initiatives, which proves valuable during audits and inspections. This proactive approach to compliance can prevent costly citations and help maintain positive relationships with regulatory bodies.

Maintenance and Longevity Considerations

Regular Inspection Protocols

To ensure consistent performance, safety mats require regular inspection and maintenance. This includes checking for physical damage, testing pressure sensitivity, and verifying proper connection to control systems. Establishing a routine maintenance schedule helps identify potential issues before they compromise safety functionality.

Documentation of inspection results and any necessary repairs provides valuable data for system optimization and compliance purposes. Training maintenance personnel in proper inspection techniques ensures thorough evaluation of all critical components.

Environmental Adaptations

Different industrial environments present unique challenges for safety mat implementation. Exposure to chemicals, extreme temperatures, or heavy foot traffic may require specific mat configurations or additional protective measures. Understanding these environmental factors enables proper selection and protection of safety mat systems.

Regular cleaning and appropriate surface treatment help maintain the anti-slip properties and sensing capabilities of safety mats. Adapting maintenance procedures to specific environmental conditions extends system longevity and ensures reliable operation.

Future Trends in Safety Mat Technology

Smart Integration and Monitoring

The future of safety mats lies in their integration with smart factory systems and Industry 4.0 technologies. Advanced sensors and communication capabilities enable real-time monitoring of mat status, predictive maintenance alerts, and detailed usage analytics. This data-driven approach enhances both safety and operational efficiency.

Emerging technologies include wireless connectivity options, enhanced diagnostic capabilities, and integration with facility-wide safety management systems. These innovations promise to make safety mat systems more responsive and easier to maintain.

Sustainable Design Developments

Manufacturers are increasingly focusing on sustainable materials and energy-efficient designs for safety mat systems. New manufacturing processes reduce environmental impact while maintaining or improving durability and performance. These developments align with growing industry emphasis on environmental responsibility.

Recyclable materials and extended product lifecycles contribute to reduced waste and lower long-term costs. Future developments may include self-powered sensing systems and biodegradable components.

Frequently Asked Questions

How long do safety mats typically last in industrial settings?

With proper maintenance and regular inspections, industrial safety mats typically last between 5-7 years. However, this lifespan can vary significantly based on usage intensity, environmental conditions, and maintenance practices. Regular testing and documentation of mat performance helps determine optimal replacement timing.

Can safety mats be customized for specific industrial applications?

Yes, safety mats can be customized in terms of size, sensitivity, and configuration to meet specific application requirements. Manufacturers offer various options for mat thickness, surface texture, and connection types to accommodate different industrial environments and safety needs.

What maintenance is required for safety mat systems?

Regular maintenance includes visual inspection for damage, testing of pressure sensitivity and response time, cleaning of surfaces, and verification of electrical connections. Monthly inspections are recommended, with more frequent checks in harsh environments or high-traffic areas. Professional assessment should be conducted annually to ensure optimal system performance.