Zrozumienie kluczowej roli mechanizmów bezpieczeństwa w nowoczesnych środowiskach przemysłowych

W dzisiejszym szybko rozwijającym się środowisku przemysłowym bezpieczeństwo pozostaje najwyższym priorytetem we wszystkich operacjach. Na czele innowacji w zakresie bezpieczeństwa stoi przełącznik paska ciśnienia , zaawansowana, a zarazem niezawodna technologia, która zrewolucjonizowała sposób podejścia do ochrony na miejscu pracy. Te specjalistyczne czujniki stały się nieodzowne w zakładach produkcyjnych, automatycznych drzwiach oraz w obsłudze ciężkiego sprzętu, oferując inteligentne rozwiązanie zapobiegające wypadkom i chroniące zarówno pracowników, jak i sprzęt.

Wdrożenie przełączników taśmowych reagujących na nacisk stanowi istotny postęp w protokołach bezpieczeństwa przemysłowego. Urządzenia te działają zgodnie z prostym, lecz skutecznym zasadą: wykrywają nacisk przyłożony wzdłuż ich długości, co powoduje natychmiastowe uruchomienie mechanizmów reakcji. Ich uniwersalność i niezawodność sprawiły, że stały się niezbędnym elementem współczesnych systemów bezpieczeństwa przemysłowego, szczególnie w obszarach, gdzie tradycyjne środki ochrony mogą okazać się niewystarczające.

Podstawowe komponenty i mechanika działania

Architektura techniczna przełączników taśmowych reagujących na nacisk

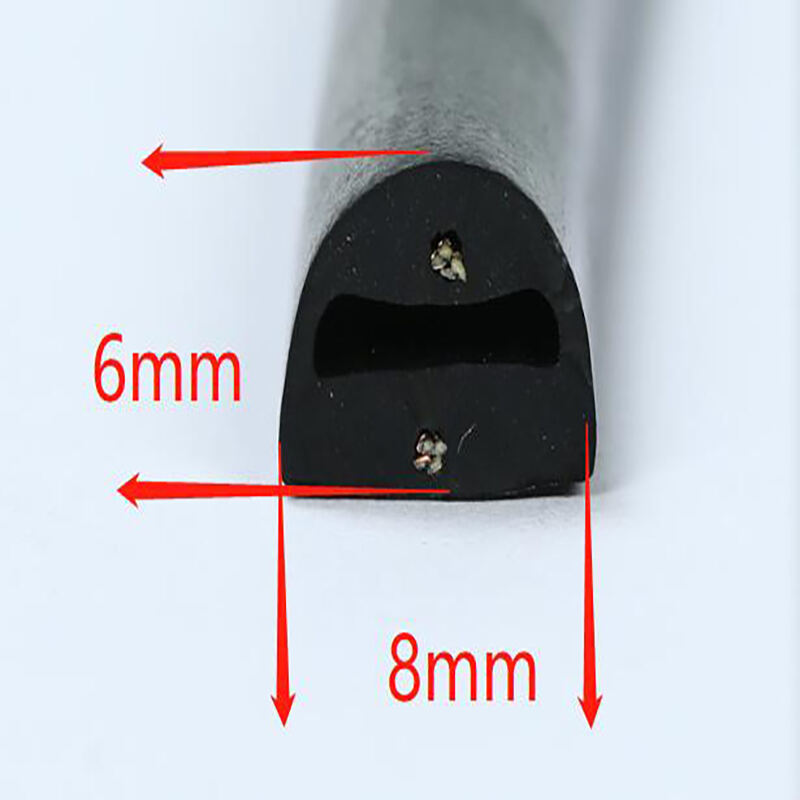

Przełącznik taśmy ciśnieniowej składa się z kilku kluczowych elementów działających zharmonizowanie. W jego centrum znajduje się giętka obudowa zewnętrzna, wykonana zazwyczaj z wytrzymałego kauczuku lub PCW, zaprojektowana tak, aby wytrzymać trudne warunki przemysłowe. Wewnątrz tej ochronnej obudowy znajdują się specjalnie zaprojektowane elementy przewodzące, które tworzą obwód elektryczny reagujący na ciśnienie zewnętrzne. Mechanizm wewnętrzny zawiera materiały czułe na ciśnienie, które mogą wykrywać siłę z dowolnego kąta, zapewniając spójne działanie niezależnie od sposobu przyłożenia nacisku.

Nowoczesne przełączniki taśmy ciśnieniowej wykorzystują zaawansowane materiały, które zapewniają zarówno trwałość, jak i czułość. Warstwy przewodzące są precyzyjnie zaprojektowane, aby zachować optymalną odległość styków, podczas gdy obudowa zewnętrzna chroni przed pyłem, wilgocią i ekspozycją na chemikalia. Taka solidna konstrukcja gwarantuje niezawodne działanie nawet w trudnych warunkach przemysłowych.

Mechanizmy wykrywania i systemy reakcji

Możliwość odbioru przez matę czujnikową ciśnienia opiera się na zaawansowanej technologii wykrywania ciśnienia. Gdy siła zostanie przyłożona do dowolnego punktu na taśmie, wewnętrzne elementy przewodzące wykonują kontakt, zamykając obwód elektryczny. Natychmiastowa reakcja uruchamia podłączony system bezpieczeństwa, który może zainicjować różne działania – od zatrzymania maszyn po aktywację sygnałów ostrzegawczych.

Czas reakcji tych systemów ma kluczowe znaczenie w zastosowaniach związanych z bezpieczeństwem. Nowoczesne maty czujnikowe ciśnienia są zaprojektowane tak, aby reagować w ciągu kilku milisekund od wykrycia ciśnienia, zapewniając szybką reakcję niezbędną do zapobiegania wypadkom w dynamicznych środowiskach przemysłowych. Czułość można często skalibrować, dostosowując ją do konkretnych wymagań aplikacji, co gwarantuje optymalną wydajność w różnych warunkach.

Wdrożenie w sektorach przemysłowych

Produkcja i linie montażowe

W zakładach produkcyjnych przełączniki naciskowe pełnią kluczową rolę w ochronie pracowników i sprzętu. Zazwyczaj montuje się je wzdłuż krawędzi ruchomych maszyn, systemów przenośników oraz komórek roboczych z robotami. Gdy są integrowane z liniami montażowymi, te przełączniki tworzą niewidzialne bariery bezpieczeństwa, które natychmiast zatrzymują pracę w przypadku nieoczekiwanego kontaktu.

Uniwersalność przełączników naciskowych czyni je szczególnie wartościowymi w zautomatyzowanych środowiskach produkcyjnych. Mogą być skonfigurowane tak, aby chronić zarówno operatorów, jak i cenny sprzęt, oferując dwufunkcyjne rozwiązanie bezpieczeństwa, które pomaga utrzymać efektywność pracy i zapewnia zgodność z przepisami dotyczącymi bezpieczeństwa na stanowisku pracy.

Zautomatyzowane systemy drzwi i bram

Zastosowanie przełączników taśmowych ciśnieniowych w systemach automatycznych drzwi i bram znacząco zwiększyło bezpieczeństwo na rampach załadunkowych, wejściach do magazynów oraz przemysłowych drzwiach garażowych. Przełączniki te są zazwyczaj montowane wzdłuż przednich krawędzi ruchomych drzwi, uniemożliwiając ich zamknięcie w przypadku wykrycia przeszkody. To rozwiązanie znacznie zmniejszyło liczbę wypadków związanych z pracą automatycznych drzwi.

Zaawansowane instalacje przełączników taśmowych ciśnieniowych w systemach drzwiowych często obejmują nadmiarowe funkcje bezpieczeństwa oraz możliwość samodzielnego monitorowania. Te ulepszone funkcje zapewniają stabilną wydajność i natychmiastowe powiadomienie, gdy system wymaga konserwacji lub kalibracji, utrzymując optymalny poziom bezpieczeństwa w każdej chwili.

Zaawansowane funkcje bezpieczeństwa i integracja

Inteligentne Monitorowanie i Diagnostyka

Nowoczesne przełączniki ciśnieniowe wyposażone są w zaawansowane systemy monitorujące, które ciągle oceniają ich stan operacyjny. Te inteligentne funkcje mogą wykrywać potencjalne problemy zanim staną się krytyczne, umożliwiając konserwację prewencyjną i zmniejszając przestoje systemu. Integracja możliwości diagnostycznych zapewnia, że systemy bezpieczeństwa pozostają niezawodne i skuteczne przez cały okres ich eksploatacji.

Najnowa generacja przełączników ciśnieniowych często obejmuje opcje łączności sieciowej, umożliwiając monitorowanie w czasie rzeczywistym i zbieranie danych. Ta integracja z systemami sterowania przemysłowego dostarcza cennych informacji na temat wydajności systemów bezpieczeństwa i pomaga optymalizować harmonogramy konserwacji.

Dostosowanie i adaptacyjność

Jedną z kluczowych zalet przełączników taśmowych ciśnieniowych jest ich dopasowanie do różnych zastosowań przemysłowych. Producenci mogą dostosować te urządzenia pod względem rozmiaru, czułości i ochrony środowiskowej, aby spełnić konkretne wymagania. Ta elastyczność umożliwia optymalne rozwiązania bezpieczeństwa w zróżnicowanych środowiskach przemysłowych, od pomieszczeń czystych po surowe warunki zewnętrzne.

Możliwość dostosowania przełączników taśmowych ciśnieniowych odnosi się również do ich integracji z istniejącymi systemami bezpieczeństwa. Nowoczesne konstrukcje mogą współpracować z różnymi systemami sterowania i protokołami bezpieczeństwa, co czyni je wartościowymi elementami kompleksowych sieci bezpieczeństwa przemysłowego.

Rozważania dotyczące konserwacji i trwałości

Protokoły Konserwacji Zabiegowej

Aby zapewnić długotrwałą niezawodność, przełączniki taśmowe ciśnieniowe wymagają regularnej konserwacji i inspekcji. Odpowiednie protokoły konserwacji obejmują badanie fizyczne pod kątem zużycia lub uszkodzeń, testowanie mechanizmów reakcji oraz weryfikację połączeń elektrycznych. Te rutynowe kontrole pomagają wykryć potencjalne problemy zanim wpłyną na skuteczność bezpieczeństwa.

Profesjonalne programy konserwatorskie często obejmują dokumentowane harmonogramy inspekcji i testowania wydajności. Takie systematyczne podejście pomaga utrzymać zgodność z przepisami bezpieczeństwa oraz wydłuża okres użytkowania systemu przełączników taśmowych ciśnieniowych.

Wpływ środowiskowy i trwałość

Nowoczesne przełączniki taśmowe ciśnieniowe są projektowane tak, aby wytrzymać trudne warunki środowiskowe w przemyśle. Wysokiej jakości materiały i solidne techniki konstrukcyjne zapewniają odporność na zmiany temperatury, ekspozycję na chemikalia oraz obciążenia fizyczne. Trwałość ta przyczynia się zarówno do niezawodności bezpieczeństwa, jak i opłacalności na dłuższą metę.

Rozważania środowiskowe obejmują również aspekty zrównoważonego rozwoju systemów przełączników taśmowych ciśnieniowych. Wiele producentów oferuje obecnie ekologiczne wersje, które minimalizują wpływ na środowisko, zapewniając jednocześnie wysoki poziom bezpieczeństwa.

Często zadawane pytania

Jakie czynniki należy wziąć pod uwagę przy wyborze przełącznika taśmowego ciśnieniowego?

Podczas wyboru przełącznika maty ciśnieniowej należy wziąć pod uwagę środowisko pracy, wymagany poziom czułości, potrzeby dotyczące czasu reakcji oraz wymagania integracyjne z istniejącymi systemami bezpieczeństwa. Dodatkowymi czynnikami są wymiary fizyczne obszaru zastosowania, ekspozycja na warunki środowiskowe oraz konkretne przemysłowe standardy zgodności.

Jak często należy testować i konserwować przełączniki mat ciśnieniowych?

Regularne testy powinny być wykonywane co najmniej raz na kwartał, z częstszymi inspekcjami w środowiskach o intensywnym użyciu lub trudnych warunkach. Codzienne inspekcje wizualne są zalecane, tak jak miesięczne testy funkcjonalne i kompleksowe roczne oceny przeprowadzane przez wykwalifikowanych techników.

Czy przełączniki mat ciśnieniowych można integrować z istniejącymi systemami bezpieczeństwa?

Tak, nowoczesne przełączniki ciśnieniowe są projektowane z uniwersalnymi możliwościami integracji. Mogą być podłączane do różnych systemów sterowania, sterowników PLC i przekaźników bezpieczeństwa. Wiele modeli oferuje wiele opcji wyjścia i protokołów komunikacyjnych, aby zapewnić kompatybilność z istniejącą infrastrukturą.