High Temperature Resistant Silicone Foam Sealing Strip Shock Absorbing And Anti Collision Low Temperature Resistant Silicone Sponge Square Strip Wear Resistant Rubber Adhesive Sealing Strip

High Temperature Resistant Silicone Foam sealing strip

Material: Silicone

Processing method: Extrusion molding

Sealing medium: Mineral lubricating oil

Industry certification: ISO9001 certification

Flame retardant grade: V-0

- Overview

- Display

- Recommended Products

- Excellent high and low temperature resistance: Conventional models can maintain elasticity for a long time in the temperature range of -50 ℃ to 250 ℃, and some special models can even withstand extreme temperatures of -70 ℃ to 300 ℃. This allows it to work reliably even in extreme environments.

- Porous structure and lightweight: It has a sponge like porous structure with a density range typically between 0.2~0.85g/cm ³ (some models can reach 0.2~1.0g/cm ³). This lightweight feature helps to reduce the overall weight of end products.

- Excellent elasticity and rebound: Low compression permanent deformation rate (≤ 15%, tested after 72 hours), which means that the rebound performance can still be maintained at over 90% after long-term compression, making it less prone to permanent deformation

- Good physical and mechanical properties: wide Shore hardness range (8~70A), tensile strength ≥ 0.8MPa (some high-performance models can reach 3.5MPa or higher), elongation at break ≥ 200%, able to withstand certain mechanical stresses

- Surface crust and uniform foaming: The surface forms a smooth crust layer, while the interior has a uniform foaming structure, which not only looks good, but also facilitates sealing and protection

- Safety environmental protection and biocompatibility: certified by international standards such as ROHS, SGS, FDA, etc., non-toxic and odorless, some models have good biocompatibility (certified by ISO 10993), and can be used in medical and food contact fields

- Good flame retardancy: reaching UL94 V-0 level (1.6mm thickness specimen), with a limit oxygen index of ≥ 32%, effectively suppressing flame spread.

- Strong weather resistance: able to resist ozone, ultraviolet (UV), and radiation, with no cracking after 1000 hours in an environment with an ozone concentration of 50pphm.

- High chemical stability: It has good tolerance to acid and alkali (pH 2-12), fuel oil, lubricating oil, etc.

- Electrical insulation: high breakdown voltage (15-25KV/mm), volume resistivity ≥ 1 × 10 ^ 14 Ω· cm, even if the silicon dioxide generated after combustion is still an insulator, ensuring the safety of electrical equipment in unexpected situations.

- Excellent sealing performance: It can effectively prevent dust, moisture, and water (up to IP68 level), be airtight and light blocking, and resist small particles and rain.

- Significant thermal insulation effect: low thermal conductivity (0.035-0.065 W/(m · K)), better insulation and energy-saving effect than many traditional materials, helping to reduce energy consumption.

- Sound insulation shock absorption and noise reduction: It can effectively absorb vibrations (energy absorption rate ≥ 60%) and isolate noise (noise reduction coefficient NRC 0.6-0.8, can isolate environmental noise above 30dB), improving the comfort and safety of equipment operation.

- High durability and reliability: resistant to aging and fatigue, with a long service life (such as a weather resistance life of more than 15 years in the field of rail transit), able to maintain stable performance for a long time, reduce maintenance costs and replacement frequency.

- Strong environmental adaptability: able to adapt to harsh outdoor climates, resistant to chemical media, UV and ozone, with a wide range of applications.

- Easy installation and flexible design: Various complex shapes and cross-sectional structures (such as I-beams and profiles) can be customized according to needs, providing precise tolerance control of ± 0.05mm for easy installation and integration.

- New Energy Vehicles and Transportation:Sealing of Power Battery Pack (Dustproof, Waterproof, Thermal runaway prevention), Waterproof Charging Interface, Motor Insulation Gasket, High Speed Rail/Car Door and Window Sealing Strip, Marine Shock Absorber, Hydraulic System Sealing Component

- Industry and Manufacturing: Industrial equipment shock pads, pipeline/boiler insulation layers, mechanical seals, precision instrument shock pads, sealing and insulation of high-temperature components inside printers/fax machines

- Medical Devices and Health: Electromagnetic shielding and sealing of medical devices such as CT machines, high-temperature sterilization packaging of surgical instruments, drainage tubes, biomimetic products

- Architecture and Home Furnishings: High rise building curtain wall sealing (weather resistance, sound insulation), three-level sealing system for doors and windows, door seals for household appliances (ovens, refrigerators, disinfection cabinets, pressure cookers, etc.)

- Electronic appliances and energy: thermal insulation and flame retardant layer for energy storage battery packs, insulation layer for wires and cables, lead wires, waterproof sealing and buffering for electronic devices (mobile phones, computers), sealing for LED lighting fixtures

- Aerospace and Special: Aircraft door/instrument panel seals, spacecraft seals (low release), oxygen supply system seals/diaphragms/valves

- Consumption and daily use: sports equipment protective gear (helmet lining, knee pads), kitchen utensils (bottle and jar sealing), hot stamping printing equipment, stationery, toys, food grade contact products

What benefits can we bring to our customers?

1.We are a manufacturer that can offer customers preferential prices and have an absolute price advantage

2. We can create customized drawings for customers free of charge until they are satisfied.

3. We can provide comprehensive online guidance to solve customers' practical problems.

4. Our company can provide the most favorable, efficient, and customer friendly transportation solutions.

5. Our company accepts various payment methods, such as VTB, Visa, Paypal, China UnionPay, etc

What advantages do we have?

1.We have nearly 20 years of production experience and are well versed in product parameters, able to solve any difficult problems for customers.

2. We have the most advanced equipment and instruments to ensure the accuracy and stability of product data.

3. We have 50 professional technical experts and teams, constantly optimizing and updating our products.

4.Our company has over 200 staff members, each with clear job responsibilities to ensure timely delivery of products.

Specifications

| Property | Technical Parameters |

| Name | Silicone foam strip High temperature corrosion and aging resistant oven sealing strip |

| Color | Red Black White Or Customize |

| Material | Silicone |

| Processing method | Extrusion molding |

| Environmental certification | ROSH certification |

| Operating temperature | -20 ℃ -200 ℃ |

| Industry certification | ISO |

| Flame retardant grade | V-0 |

| Features | Wear resistant waterproof corrosion-resistant high and low temperature resistant strong sealing performance |

Features of silicone foam strip

Core advantages of silicone foam strip

Application scenarios of silicone foam strips

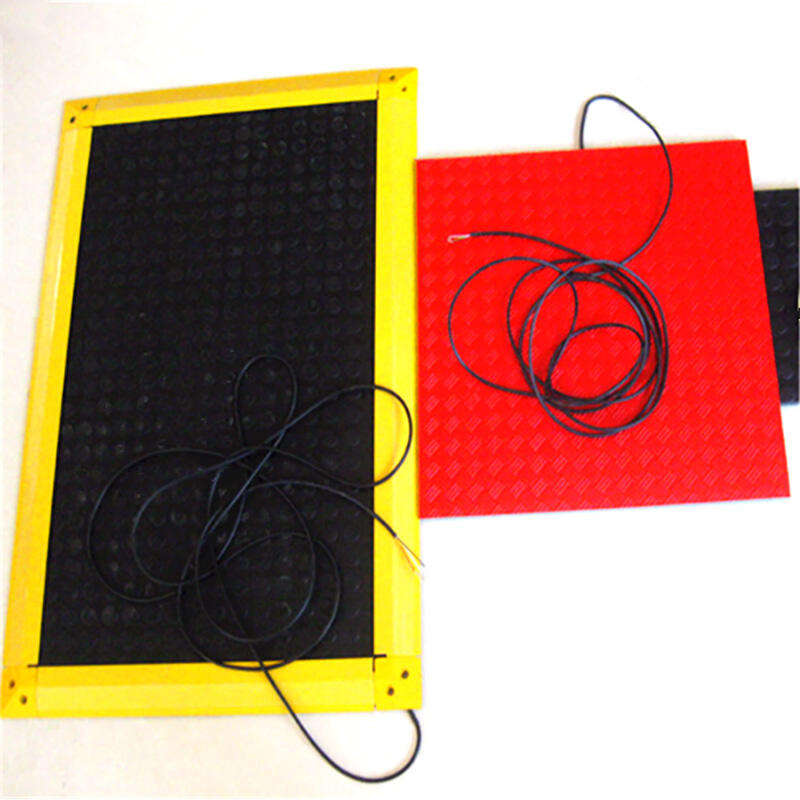

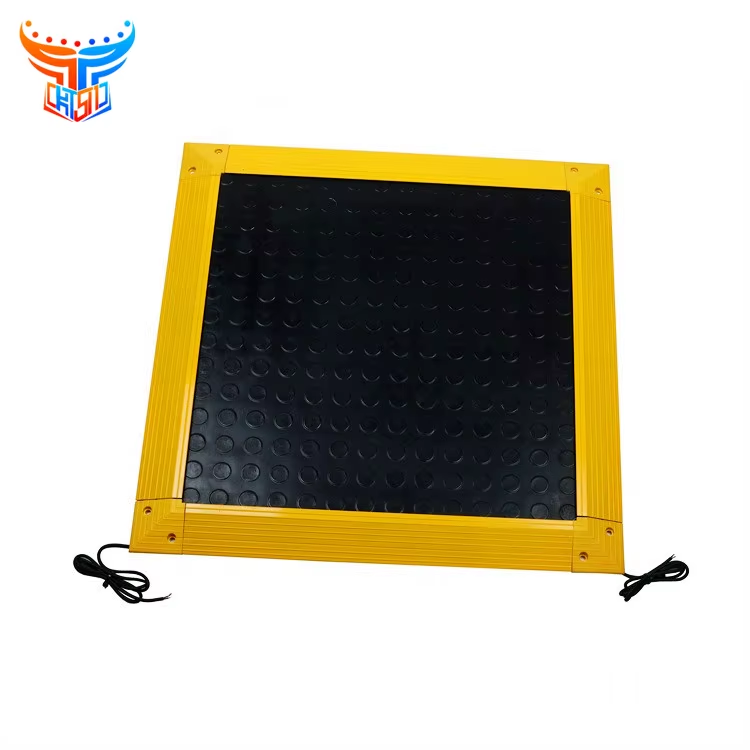

Product real-life photo display

Factory actual photo

Sufficient inventory

Exhibition Display